Power Factor In An Ac Circuit

Juapaving

Mar 22, 2025 · 6 min read

Table of Contents

Power Factor in an AC Circuit: A Comprehensive Guide

Power factor (PF) is a crucial concept in alternating current (AC) circuits, representing the efficiency of electrical power utilization. Understanding power factor is essential for optimizing energy consumption, preventing equipment damage, and ensuring stable electrical systems. This comprehensive guide delves into the intricacies of power factor, exploring its causes, consequences, and methods of improvement.

What is Power Factor?

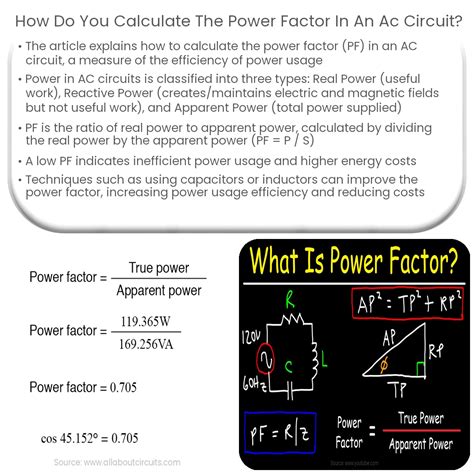

Power factor is the ratio of real power (kW) to apparent power (kVA) in an AC circuit. It's a dimensionless number ranging from 0 to 1, often expressed as a percentage.

-

Apparent Power (S): This is the total power supplied to the circuit, encompassing both real and reactive power. It's calculated as the product of voltage and current (S = V x I). Measured in kilovolt-amperes (kVA).

-

Real Power (P): This is the actual power consumed and used to perform work. It's the power dissipated as heat or mechanical energy. Measured in kilowatts (kW).

-

Reactive Power (Q): This is the power that oscillates between the source and the load, not contributing to actual work. It's associated with energy stored in and released from inductive and capacitive elements. Measured in kilovolt-amperes reactive (kVAR).

The relationship between these powers is defined by the power triangle:

S² = P² + Q²

The power factor is then calculated as:

Power Factor (PF) = P / S = kW / kVA

A power factor of 1 indicates perfect efficiency, with all supplied power being consumed as real power. A power factor less than 1 indicates the presence of reactive power, representing inefficiency.

Causes of Low Power Factor

Low power factor is primarily caused by inductive loads, such as motors, transformers, and fluorescent lights. These loads store energy in magnetic fields, causing a phase shift between voltage and current. This phase difference reduces the real power delivered to the load while increasing the apparent power.

Capacitive loads, while less common, can also contribute to a low power factor, albeit in the opposite direction. Capacitors store energy in electric fields, leading to a different type of phase shift. However, in most industrial settings, inductive loads are the dominant factor.

Understanding the Phase Shift

The key to understanding low power factor is the phase relationship between voltage and current. In a purely resistive circuit, voltage and current are in phase (0° phase difference), resulting in a power factor of 1. However, in inductive circuits, the current lags behind the voltage, creating a phase difference (typically between 0° and 90°). This lagging current contributes to reactive power, lowering the power factor. In capacitive circuits, the current leads the voltage.

Consequences of Low Power Factor

A low power factor has several detrimental effects:

-

Increased Energy Costs: Utilities often charge penalties for low power factors because it necessitates larger generators and transmission lines to deliver the same amount of real power. This increased capacity translates directly to higher energy bills.

-

Oversized Equipment: To deliver the required real power, equipment must be oversized to handle the higher apparent power. This leads to higher capital costs and increased energy consumption.

-

Voltage Drop: Low power factor can cause excessive voltage drops in the distribution system, leading to reduced efficiency and potential equipment damage.

-

Reduced System Capacity: The apparent power, not the real power, determines the capacity of electrical equipment. A low power factor limits the amount of real power that can be delivered without overloading the system.

-

Increased Heating: Higher currents associated with low power factor lead to increased heat generation in equipment, reducing efficiency and potentially shortening the lifespan of components.

Improving Power Factor

Fortunately, several methods can be employed to improve the power factor:

1. Power Factor Correction (PFC) Capacitors:

This is the most common method, involving the strategic installation of capacitors in parallel with inductive loads. Capacitors provide leading reactive power that compensates for the lagging reactive power produced by the inductive loads, effectively reducing the overall reactive power and improving the power factor. The capacitance value needs to be carefully calculated to achieve the desired power factor improvement.

2. Synchronous Motors:

Synchronous motors can operate at leading power factor, effectively counteracting the lagging power factor of inductive loads. However, they are generally more expensive than other methods.

3. Power Factor Correction Equipment:

Specialized equipment, such as static VAR compensators (SVCs) or static synchronous compensators (STATCOMs), actively control reactive power to optimize the power factor. These are more advanced and costly solutions, typically used in large industrial applications.

4. Replacing Inefficient Equipment:

Replacing old, inefficient equipment with more modern, energy-efficient alternatives can inherently improve the power factor. New motors and lighting often have improved power factor characteristics.

5. Optimized Load Management:

Carefully scheduling and managing loads can reduce peak demand and improve the overall power factor. This involves strategic control of energy-intensive processes to balance inductive and capacitive loads throughout the day.

Measuring Power Factor

Power factor can be measured using various instruments:

-

Power Meters: These meters directly measure real power, apparent power, and power factor. They provide a clear indication of the power factor and its effect on energy consumption.

-

Clamp Meters: Clamp meters can measure current and voltage, allowing for the indirect calculation of apparent power and power factor.

-

Multimeters: While not as precise, some multimeters can measure power factor, though their accuracy may be limited.

The choice of instrument depends on the application and the level of accuracy required.

Power Factor and Different Types of Loads

The power factor varies significantly depending on the type of load:

-

Resistive Loads: These loads (like incandescent lighting or electric heaters) have a power factor close to 1.

-

Inductive Loads: These loads (like motors, transformers, and inductors) generally exhibit a lagging power factor significantly less than 1.

-

Capacitive Loads: These loads (like capacitors and some power supplies) generally exhibit a leading power factor. However, in most practical scenarios, the inductive loads outweigh the capacitive loads.

Understanding the characteristics of different load types is essential for effective power factor correction.

Power Factor Improvement Strategies for Specific Industries

Different industries have unique power factor challenges and require tailored solutions:

-

Manufacturing: Factories with a high concentration of motors and industrial equipment often require significant power factor correction measures, such as PFC capacitors or more advanced solutions like SVCs.

-

Commercial Buildings: Office buildings and retail spaces can benefit from power factor correction through upgrades to lighting systems, HVAC equipment, and the installation of PFC capacitors.

-

Data Centers: Data centers consume immense amounts of power, and efficient power factor management is crucial for minimizing energy costs and ensuring reliable operation.

-

Residential Settings: While residential power factor issues are typically less significant, using energy-efficient appliances and lighting can still improve overall efficiency.

Conclusion: The Importance of Power Factor Optimization

Power factor plays a crucial role in the efficient and cost-effective use of electrical power. A low power factor leads to increased energy costs, oversized equipment, and reduced system capacity. By understanding the causes and consequences of low power factor and implementing appropriate correction measures, businesses and individuals can significantly improve energy efficiency, reduce operational costs, and contribute to a more sustainable energy future. Regular monitoring and assessment of power factor are key to maintaining optimal performance and avoiding unnecessary energy waste. Remember that a proactive approach to power factor management is essential for long-term cost savings and enhanced system reliability. Investing in power factor correction is not just about reducing bills; it's about ensuring the efficient and sustainable operation of electrical systems.

Latest Posts

Latest Posts

-

Neutral Atoms Have The Same Number Of

Mar 24, 2025

-

Center Of Mass Of An Equilateral Triangle

Mar 24, 2025

-

Non Superimposable Mirror Images Are Called

Mar 24, 2025

-

The Amount Of Space Between Two Points

Mar 24, 2025

-

What Is The Greatest Common Multiple Of 3 And 4

Mar 24, 2025

Related Post

Thank you for visiting our website which covers about Power Factor In An Ac Circuit . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.