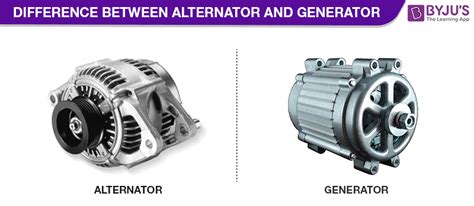

Difference Between A Generator And Alternator

Juapaving

Mar 15, 2025 · 6 min read

Table of Contents

Generators vs. Alternators: Understanding the Key Differences

The terms "generator" and "alternator" are often used interchangeably, leading to confusion. While both devices convert mechanical energy into electrical energy, there are fundamental differences in their design, operation, and applications. This comprehensive guide will delve into the specifics, clarifying the distinctions and helping you understand when to use each type of machine.

Defining the Terms: Generator and Alternator

Let's start with clear definitions:

Generator: A generator is a broad term encompassing any device that converts mechanical energy into electrical energy. This conversion can be achieved through various principles, including electromagnetic induction (as in alternators and dynamos) and other less common methods. Generators can produce both alternating current (AC) and direct current (DC).

Alternator: An alternator is a specific type of generator that produces alternating current (AC). It's based on the principle of electromagnetic induction, employing rotating magnetic fields to induce an alternating voltage in stationary coils. Alternators are almost exclusively used in vehicles and power generation systems requiring AC electricity.

Core Differences: AC vs. DC Output

The most significant difference lies in their output:

-

Alternators produce alternating current (AC): AC voltage constantly changes its polarity, oscillating between positive and negative values. This makes AC easily transformable to different voltage levels using transformers, enabling efficient long-distance power transmission.

-

Generators can produce either alternating current (AC) or direct current (DC): DC voltage maintains a constant polarity, flowing in one direction only. While DC is suitable for many applications, especially those requiring specific voltage levels, it's less efficient for long-distance transmission. Generators that produce DC are often called dynamos.

This fundamental difference in output influences their design, components, and applications.

Construction and Operational Principles: A Deeper Dive

The internal workings of generators and alternators differ considerably, reflecting their distinct output characteristics:

Alternator Construction and Operation

An alternator typically consists of:

-

Stator: A stationary part containing coils of wire embedded in slots within a laminated iron core. The AC voltage is induced in these stator coils. The stator's design is crucial for determining the alternator's output voltage and frequency.

-

Rotor: A rotating part, usually equipped with permanent magnets or electromagnets, creating a rotating magnetic field. The rotation of the rotor induces an alternating electromotive force (EMF) in the stator coils. The speed of the rotor directly influences the frequency of the AC output. Higher rotor speeds produce higher frequencies.

-

Rectifier (optional): Some alternators include a rectifier to convert the generated AC to DC. This is commonly seen in car alternators which supply DC power to the vehicle's electrical system.

The alternator's operation relies on Faraday's law of electromagnetic induction. As the rotor rotates, the magnetic flux linking the stator coils changes continuously, inducing an alternating current in the coils. The frequency of this current is directly proportional to the rotational speed of the rotor.

Generator Construction and Operation

Generator construction varies greatly depending on the type of output (AC or DC) and the method of energy conversion. However, most generators that produce DC, also known as dynamos, employ:

-

Armature: A rotating component containing coils of wire. The armature's rotation within a magnetic field induces an EMF in the coils.

-

Field Magnets: Stationary magnets (permanent or electromagnets) which create the magnetic field within which the armature rotates.

-

Commutator: A segmented ring attached to the armature, converting the AC voltage generated in the coils to DC voltage. The commutator ensures that the current always flows in the same direction in the external circuit.

DC generators use a commutator to rectify the inherently AC voltage induced in the rotating armature. This rectification process ensures a unidirectional current flow in the external circuit. AC generators, however, don't require this commutator, relying solely on electromagnetic induction in stationary coils.

Applications: Where Each Shines

The choice between an alternator and a generator depends heavily on the specific application:

Alternator Applications:

-

Automotive industry: Alternators are the ubiquitous power source in vehicles, providing AC power that's then rectified to DC for charging the battery and powering electrical accessories.

-

Power generation: Large-scale power plants use alternators to generate the AC power that feeds into the electrical grid. These alternators are significantly larger and more powerful than those found in vehicles.

-

Industrial applications: Numerous industrial processes rely on AC power generated by alternators. This includes machinery, lighting, and various other electrical equipment.

-

Renewable energy systems: Alternators are central components in wind turbines and hydropower generators, converting mechanical energy from rotating blades or turbines into AC electricity.

Generator Applications:

-

Backup power: DC generators can act as backup power sources in case of power outages. They can power essential equipment such as lights and medical devices.

-

Specialized applications: Some equipment requires a constant DC supply and DC generators are ideal for this purpose. This includes older electronic devices and certain types of industrial machinery.

-

Small-scale power generation: Smaller DC generators can be used in remote locations or situations where AC power isn't readily available.

-

Electroplating: DC generators are utilized in electroplating processes, providing a stable current for metal coating.

Efficiency and Regulation: A Comparative Look

Both alternators and generators have varying levels of efficiency and need regulation to maintain stable output voltage and frequency:

Efficiency:

-

Alternators generally exhibit higher efficiency than DC generators: This is due to the absence of brushes and commutators, which contribute to energy losses in DC generators. The lack of friction and sparking results in less energy waste.

-

Efficiency varies based on design and load: Both alternator and generator efficiency depends heavily on factors such as design, size, load, and maintenance.

Regulation:

-

Alternators require voltage regulators: These regulators control the excitation current to maintain a constant voltage output despite variations in load.

-

DC generators require voltage regulators as well: Similar to alternators, regulators are crucial to maintain a stable output voltage. These regulators can vary in complexity, depending on the type of generator and the required precision.

Advantages and Disadvantages: Summarizing the Key Points

Let's summarize the key advantages and disadvantages of alternators and generators:

Alternators: Advantages

- Higher efficiency: Reduced energy loss compared to DC generators due to the absence of brushes and commutators.

- Easy voltage transformation: AC power can be easily transformed to different voltage levels using transformers.

- Suitable for large-scale power generation: Ideal for generating power for electrical grids.

- Simple and robust construction (compared to many types of generators): Generally less complex and easier to maintain.

Alternators: Disadvantages

- Requires rectification for DC applications: Additional components are necessary to convert the AC output to DC power for certain applications.

- Can be affected by fluctuations in the speed of the prime mover: The output frequency is directly related to the rotor's speed.

Generators (DC): Advantages

- Direct DC output: Suitable for applications requiring a stable DC power source.

- Wide range of applications: Useful in many settings where stable DC is required, including specialized equipment and backup power systems.

Generators (DC): Disadvantages

- Lower efficiency compared to alternators: Energy losses due to brushes and commutators.

- Complex regulation required for stable voltage output: Maintenance and adjustment can be more involved.

- Less suitable for large-scale power generation: Not as practical as alternators for high-power applications.

Conclusion: Choosing the Right Device

The choice between an alternator and a generator depends entirely on the specific application's needs. Alternators dominate in scenarios requiring high-efficiency AC power generation for large-scale systems or applications where voltage transformation is essential. DC generators, however, remain valuable for niche applications needing direct DC power, specialized equipment, or situations with smaller-scale requirements. Understanding these core differences will ensure you select the optimal device for your specific needs.

Latest Posts

Latest Posts

-

What Is The Name Of Ca No3 2

Mar 15, 2025

-

Which Pair Of Angles Is Supplementary

Mar 15, 2025

-

What Color Do Acids Turn Litmus Paper

Mar 15, 2025

-

Youngest Mountain Range In The World

Mar 15, 2025

-

What Is Most Abundant Metal In Earths Crust

Mar 15, 2025

Related Post

Thank you for visiting our website which covers about Difference Between A Generator And Alternator . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.