Caso4 Xh2o Loses 6.2 Of Water

Juapaving

Mar 31, 2025 · 5 min read

Table of Contents

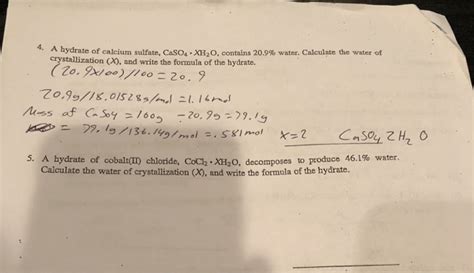

Dehydration of Caso4·xH2O: Understanding the Loss of 6.2% Water

The dehydration of hydrates, particularly those involving metal sulfates like Caso4·xH2O (calcium sulfate hydrate), is a crucial process in various chemical and industrial applications. Understanding the behavior of these hydrates, specifically the weight loss associated with water removal, is fundamental to process optimization and quality control. This article delves into the intricacies of Caso4·xH2O dehydration, focusing on the specific scenario where a 6.2% weight loss is observed due to water removal. We'll explore the underlying chemistry, the implications of this specific weight loss, and the practical considerations involved.

Understanding Calcium Sulfate Hydrates

Calcium sulfate exists in several hydrated forms, the most common being gypsum (Caso4·2H2O) and anhydrite (Caso4). Gypsum, a naturally occurring mineral, is a dihydrate, meaning it contains two molecules of water per formula unit of calcium sulfate. The water molecules are incorporated into the crystal lattice, forming specific hydrogen bonds with the sulfate and calcium ions. Heating gypsum drives off this water, resulting in a change in crystal structure and physical properties. The degree of hydration significantly impacts the material's properties, affecting its solubility, density, and reactivity.

The Dehydration Process

The dehydration of Caso4·2H2O is a stepwise process, not a single event. The first step typically involves the loss of one or more water molecules at relatively low temperatures, forming a hemihydrate (Caso4·½H2O), often called plaster of Paris. Further heating removes the remaining water, leading to the formation of anhydrous calcium sulfate (Caso4). The temperature at which these transitions occur is influenced by several factors, including the heating rate, atmospheric pressure, and the presence of impurities.

Interpreting the 6.2% Water Loss

A 6.2% weight loss in Caso4·xH2O indicates a partial dehydration, not complete conversion to anhydrous Caso4. To understand the extent of dehydration, we need to perform a stoichiometric calculation:

1. Calculate the molar mass of Caso4·2H2O:

- Ca: 40.08 g/mol

- S: 32.07 g/mol

- O (4 from Caso4 + 4 from 2H2O): 16.00 g/mol * 8 = 128.00 g/mol

- H: 1.01 g/mol * 4 = 4.04 g/mol

Total molar mass of Caso4·2H2O: 40.08 + 32.07 + 128.00 + 4.04 = 204.19 g/mol

2. Calculate the mass of water in Caso4·2H2O:

- Molar mass of water (H2O): 18.02 g/mol

- Mass of water in one mole of Caso4·2H2O: 2 * 18.02 g/mol = 36.04 g/mol

3. Calculate the percentage of water in Caso4·2H2O:

- Percentage of water = (mass of water / molar mass of Caso4·2H2O) * 100%

- Percentage of water = (36.04 g/mol / 204.19 g/mol) * 100% ≈ 17.6%

4. Determine the extent of dehydration:

Since the observed weight loss is 6.2%, we can calculate the fraction of water remaining:

- Fraction of water remaining = 1 - (6.2%/17.6%) ≈ 0.65

This suggests that approximately 35% of the water has been removed. This doesn't precisely correspond to a specific hydrate, such as the hemihydrate. The actual composition likely falls between the dihydrate and the hemihydrate, possibly representing a mixture of both or an intermediate state. The slight discrepancy from a perfectly stoichiometric ratio might be attributed to experimental error or imperfections in the crystal structure.

Factors Affecting Dehydration

Several factors can influence the dehydration process and the resulting weight loss:

Temperature:

Higher temperatures accelerate the dehydration process. However, excessively high temperatures can lead to thermal decomposition or unwanted side reactions. Finding the optimal temperature range is crucial for efficient and controlled dehydration.

Heating Rate:

A rapid heating rate might result in incomplete dehydration or the formation of metastable phases. A slower, more controlled heating rate allows for better equilibrium conditions and a more uniform dehydration.

Particle Size:

Smaller particles have a larger surface area, leading to faster dehydration rates. This is because more water molecules are accessible for evaporation.

Atmospheric Conditions:

Humidity in the surrounding atmosphere can affect the equilibrium of the dehydration reaction, potentially slowing down the process. A dry atmosphere is generally preferred for efficient dehydration.

Impurities:

The presence of impurities in the Caso4·xH2O sample can influence the dehydration kinetics and temperature. Impurities can act as nucleation sites or catalysts, affecting the reaction rate.

Applications and Implications

The controlled dehydration of Caso4·xH2O has numerous practical applications:

Cement Production:

Gypsum is used as a retarder in cement production, controlling the setting time. The hydration and dehydration properties of gypsum are crucial for regulating the cement's hardening process. The precise control of water content is critical for consistent cement quality.

Plaster and Building Materials:

Plaster of Paris (hemihydrate) is a key component in various building materials and plasters. Its production relies heavily on the controlled dehydration of gypsum. The properties of the plaster are directly related to the degree of dehydration and the subsequent hydration process during setting.

Industrial Processes:

Calcium sulfate is used in various industrial processes, including water treatment, fertilizer production, and paper manufacturing. The hydration state of the calcium sulfate can influence its efficiency and reactivity in these applications.

Analytical Chemistry:

The dehydration of Caso4·xH2O is used in gravimetric analysis to determine the water content of samples. Precise weight measurements before and after dehydration allow for the determination of the hydrate's composition.

Conclusion

The 6.2% water loss in Caso4·xH2O signifies a partial dehydration, falling between a dihydrate and a hemihydrate. The precise composition depends on several factors, including temperature, heating rate, and atmospheric conditions. Understanding the intricacies of this dehydration process is crucial for various applications, from cement production to analytical chemistry. Precise control over the dehydration process is key to ensuring the desired properties and quality of the resulting calcium sulfate material. Further investigation, potentially involving thermogravimetric analysis (TGA), could provide more detailed information about the specific dehydration stages and the resulting composition after the 6.2% weight loss. This knowledge is essential for optimizing industrial processes and achieving consistent product quality.

Latest Posts

Latest Posts

-

What Is 0 07 As A Percentage

Apr 01, 2025

-

Moment Of Inertia Of A Circle Formula

Apr 01, 2025

-

A Solenoid With A Core Is Called An Electromagnet

Apr 01, 2025

-

In An Exponential Function What Does The A Represent

Apr 01, 2025

-

When Is A Substance A Limiting Nutrient

Apr 01, 2025

Related Post

Thank you for visiting our website which covers about Caso4 Xh2o Loses 6.2 Of Water . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.