What Kind Of Energy Transformation Happens In A Generator

Juapaving

Mar 21, 2025 · 6 min read

Table of Contents

What Kind of Energy Transformation Happens in a Generator?

Generators are ubiquitous in modern society, powering everything from our homes and businesses to entire cities. But have you ever stopped to consider the fundamental physics behind their operation? At its core, a generator is a remarkable device that facilitates a crucial energy transformation: converting mechanical energy into electrical energy. This article delves deep into this process, exploring the underlying principles, different generator types, and the factors influencing their efficiency.

The Fundamental Principle: Electromagnetic Induction

The heart of a generator's operation lies in the principle of electromagnetic induction, first discovered by Michael Faraday. This principle states that a changing magnetic field can induce an electromotive force (EMF), or voltage, in a conductor. This induced voltage, in turn, can drive an electric current if a closed circuit is provided.

Understanding the Components:

A basic generator consists of three key components:

- Magnetic Field: This is typically created using permanent magnets or electromagnets. The strength and configuration of this field directly influence the generator's output.

- Conductor: This is usually a coil of wire, often wound around a rotor (rotating part). The conductor cuts through the magnetic field, inducing the voltage.

- Motion: Relative motion between the magnetic field and the conductor is absolutely crucial. This motion is what creates the changing magnetic field necessary for induction. This motion can be provided by various means, depending on the type of generator.

The Process of Energy Conversion:

-

Mechanical Energy Input: The generator's operation begins with the input of mechanical energy. This could come from various sources like:

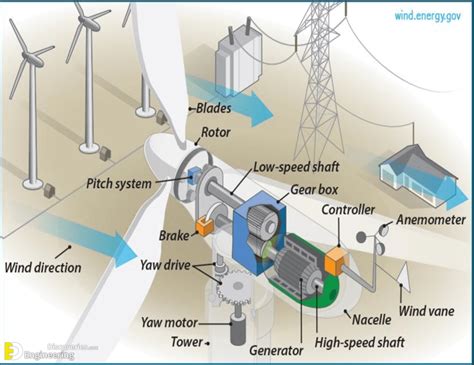

- Turbines: Driven by steam (in thermal power plants), water (in hydroelectric plants), wind (in wind turbines), or gas (in gas turbine power plants).

- Internal Combustion Engines: Commonly used in portable generators.

- Hand Cranks: Found in small, emergency generators.

-

Rotation and Magnetic Field Interaction: The mechanical energy input causes the rotor (containing the coil of wire) to rotate within the magnetic field. As the coil rotates, the magnetic flux linking the coil constantly changes.

-

Electromagnetic Induction: This changing magnetic flux induces an EMF (voltage) in the coil, according to Faraday's law of induction. The magnitude of the induced EMF is proportional to the rate of change of the magnetic flux. A faster rotation means a more rapid change in flux, resulting in a higher voltage.

-

Electrical Energy Output: The induced voltage drives a current through the coil and the external circuit connected to the generator's terminals. This is the electrical energy output of the generator. The current's direction alternates as the coil rotates, resulting in alternating current (AC) in most generators.

Types of Generators: A Deeper Dive

While the fundamental principle remains the same, different types of generators employ various mechanisms to achieve the necessary relative motion between the magnetic field and the conductor.

1. AC Generators (Alternators):

These are the most common type of generator, producing alternating current. The rotating coil generates a sinusoidal voltage that reverses direction periodically. The frequency of this alternation depends on the rotational speed of the rotor.

- Rotating Armature Alternators: In this design, the armature (coil) rotates within a stationary magnetic field produced by field coils. This is a common configuration for smaller generators.

- Rotating Field Alternators: Here, the field magnets rotate, while the armature (stator) remains stationary. This design is preferred for larger power generation systems because the stationary armature can easily handle high currents without the need for complex slip rings.

2. DC Generators:

These generators produce direct current, where the current flows in one direction only. They require a commutator – a rotating switch – to rectify the alternating current induced in the coil.

- Separately Excited DC Generators: The field magnets are supplied with current from a separate source.

- Self-Excited DC Generators: The field magnets are supplied with current from the generator itself, using residual magnetism in the field poles to initiate the process. Different types exist, such as shunt-wound, series-wound, and compound-wound generators, based on how the field windings are connected.

3. Synchronous Generators:

These generators are designed to produce AC power at a specific frequency, synchronized with the frequency of the power grid. They are widely used in power plants to supply electricity to the national grid. The rotor speed is carefully controlled to maintain the desired frequency.

4. Asynchronous Generators (Induction Generators):

These generators don't require an external excitation source, instead relying on the magnetic field of the grid to induce current in the rotor. They are usually used in small-scale applications and renewable energy systems, like wind turbines.

Factors Affecting Generator Efficiency:

Several factors influence the efficiency of a generator in converting mechanical energy to electrical energy:

- Magnetic Field Strength: A stronger magnetic field leads to higher induced voltage, improving efficiency. However, excessively strong fields can lead to saturation and reduced efficiency.

- Coil Design: The number of turns in the coil and the coil's resistance affect the voltage and current output. Optimized coil design is essential for maximizing efficiency.

- Friction and Windage Losses: Friction in the bearings and wind resistance to the rotating parts cause energy losses, reducing overall efficiency. High-quality bearings and aerodynamic design minimize these losses.

- Eddy Currents and Hysteresis Losses: Eddy currents in the core material and hysteresis losses due to the magnetization and demagnetization of the core also reduce efficiency. The use of laminated cores minimizes these losses.

- Copper Losses (I²R Losses): Resistance in the coil windings causes energy to be lost as heat (Joule heating). Using low-resistance copper wire minimizes these losses.

- Rotational Speed: The optimum rotational speed depends on the generator's design and the desired frequency of the output. Operating at the correct speed maximizes efficiency.

Generator Applications: A Broad Spectrum

The versatility of generators is evident in their widespread applications across various sectors:

- Power Generation: Large-scale power plants utilize generators driven by turbines to provide electricity to homes and businesses.

- Renewable Energy: Wind turbines and hydroelectric plants employ generators to convert mechanical energy from wind and water into electricity.

- Transportation: Generators are essential components in vehicles, supplying power for various systems, including lighting and electronics.

- Industrial Applications: Generators provide power for industrial machinery and processes in various settings.

- Emergency Power: Portable generators provide backup power during outages.

- Medical Devices: Small generators power portable medical equipment.

Conclusion: Harnessing Mechanical Energy for Electrical Needs

The energy transformation within a generator, from mechanical to electrical energy, is a testament to the ingenuity of scientific principles. Understanding the fundamental concepts of electromagnetic induction and the different generator types illuminates the sophisticated engineering behind this vital technology. While efficiency is always a key consideration, ongoing advancements in materials science and design continue to optimize generator performance, making them even more efficient and reliable in powering our increasingly electrify world. The future of energy generation will undoubtedly rely heavily on further refinement and innovation in this crucial area.

Latest Posts

Latest Posts

-

The Process Of Dna Replication Occurs Just Before

Mar 21, 2025

-

How Many Hours Is 180 Min

Mar 21, 2025

-

What Is The Natural Log Of Infinity

Mar 21, 2025

-

Templates For Letter To Claim Deceased Accounts

Mar 21, 2025

-

What Is The Third Root Of 27

Mar 21, 2025

Related Post

Thank you for visiting our website which covers about What Kind Of Energy Transformation Happens In A Generator . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.