What Is Difference Between Generator And Alternator

Juapaving

Mar 13, 2025 · 6 min read

Table of Contents

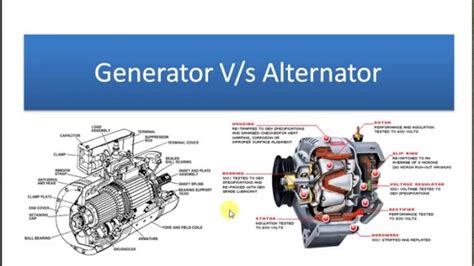

What's the Difference Between a Generator and an Alternator?

The terms "generator" and "alternator" are often used interchangeably, leading to confusion. While both devices convert mechanical energy into electrical energy, there's a crucial difference in how they achieve this conversion. Understanding this difference is vital for anyone working with power generation, automotive mechanics, or simply curious about electrical engineering. This article will delve deep into the core distinctions between generators and alternators, exploring their operating principles, applications, and key advantages and disadvantages.

Understanding the Fundamentals: Generators and Alternators

At their heart, both generators and alternators perform the same basic function: converting mechanical energy (like that from a spinning turbine or engine) into electrical energy. However, the methods they employ differ significantly. This difference lies in the type of current they produce: direct current (DC) or alternating current (AC).

Generators: The DC Powerhouses

A generator is a device that produces direct current (DC) electricity. DC is characterized by a constant flow of electrons in one direction. Think of a battery – it provides a consistent flow of DC power. Generators typically achieve this using a commutator, a rotating switch that rectifies the AC current initially produced by the rotating coils within a magnetic field.

How a Generator Works:

- Mechanical Energy Input: A prime mover (e.g., engine, turbine, water wheel) rotates a shaft.

- Rotating Coils and Magnetic Field: The shaft is connected to a rotor containing coils of wire that rotate within a stationary magnetic field (stator).

- Electromagnetic Induction: As the coils rotate, they cut through the magnetic field lines, inducing an electromotive force (EMF) and generating an alternating current (AC) within the coils.

- Commutator Action: The commutator, a segmented ring connected to the rotor coils, acts as a switch, reversing the current connections at precise points in the rotation. This rectification converts the AC into pulsating DC.

- DC Output: The pulsating DC is then often smoothed using a filter circuit to produce a more consistent DC output.

Advantages of Generators:

- Simple Construction (for smaller units): Smaller DC generators can have relatively simple designs.

- Direct Output: They produce DC directly, which is often needed in certain applications.

- Easy Voltage Regulation (for smaller units): Controlling the voltage in smaller DC generators can be straightforward.

Disadvantages of Generators:

- Maintenance: The commutator and brushes are subject to wear and require regular maintenance.

- Sparking: The commutator can cause sparking, creating a fire hazard in some environments.

- Limited Power Output: Building large, high-power DC generators is complex and inefficient compared to AC alternators.

- Inefficient for High Power Applications: DC generators become significantly less efficient as power output demands increase.

Alternators: The AC Champions

An alternator is a device that produces alternating current (AC) electricity. AC is characterized by the electrons periodically reversing their direction of flow. This cyclical change in direction allows for efficient long-distance transmission and easy voltage transformation using transformers. Alternators achieve this AC output through a straightforward design without the need for a commutator.

How an Alternator Works:

- Mechanical Energy Input: Similar to a generator, a prime mover rotates a shaft.

- Rotating Magnet (Rotor) and Stationary Coils (Stator): In most alternators, a rotating magnet (rotor) spins within a set of stationary coils of wire (stator). The opposite configuration (rotating coils and stationary magnet) is also possible.

- Electromagnetic Induction: The rotating magnetic field induces an alternating current in the stator coils.

- AC Output: The stator coils directly produce an AC output without any need for rectification.

- Voltage Regulation: Alternators incorporate voltage regulators to maintain a consistent voltage output despite varying engine speeds or loads.

Advantages of Alternators:

- Higher Efficiency: Alternators are generally more efficient than generators, especially at higher power outputs.

- No Commutator: The absence of a commutator eliminates sparking and reduces maintenance requirements.

- Higher Power Output: Alternators are readily scalable for high-power applications.

- Easy Voltage Control: Precise voltage regulation is easily achieved using electronic controls.

- Smaller and Lighter (for equivalent power): Alternators are generally more compact and lighter than comparable DC generators.

Disadvantages of Alternators:

- AC Output Requires Rectification for DC Applications: If DC is needed, additional rectification circuitry is required to convert the AC output to DC.

- More Complex Design (in some cases): While simpler than high-power DC generators, some alternator designs can be more complex than simple DC generators.

Key Differences Summarized:

| Feature | Generator (DC) | Alternator (AC) |

|---|---|---|

| Output Current | Direct Current (DC) | Alternating Current (AC) |

| Commutator | Present (Usually) | Absent |

| Efficiency | Lower, especially at high power outputs | Higher, especially at high power outputs |

| Maintenance | Higher (due to commutator and brushes) | Lower |

| Power Output | Limited for large-scale applications | Easily scalable for high-power applications |

| Voltage Regulation | Simpler for smaller units; more complex for larger ones | Easily controlled electronically |

| Applications | Smaller applications, specialized DC needs | Automotive, power generation, industrial use |

Applications of Generators and Alternators:

Both generators and alternators find use in various applications, but their suitability depends heavily on the desired type of current and power requirements.

Generator Applications:

- Small-scale power generation: For situations requiring relatively low DC power, generators can be a simple and effective solution. Examples include small wind turbines, solar power systems, and some portable power sources.

- Specialized DC equipment: Some equipment requires direct DC power, and generators provide a straightforward way to generate it. This includes certain types of motors, electrochemical processes, and some older electronic devices.

- Battery charging: DC generators are used in some applications for charging batteries directly.

Alternator Applications:

- Automotive systems: Almost all modern vehicles use alternators to generate AC power, which is then rectified to DC to power various components and charge the battery.

- Power generation plants: Large-scale power generation plants overwhelmingly use alternators to produce AC power for the electrical grid.

- Industrial applications: Alternators supply power for various industrial machines and processes.

- Uninterruptible Power Supplies (UPS): While UPS systems often provide DC, they frequently utilize alternators as part of their power generation component.

Choosing Between a Generator and an Alternator:

The choice between a generator and an alternator depends primarily on the specific application requirements:

- Need for DC Power: If the application requires DC power directly, a generator might be considered, though rectifying AC from an alternator is often more efficient for higher power needs.

- Power Requirements: For high-power applications, alternators are generally the preferred choice due to their higher efficiency and scalability.

- Maintenance Considerations: If minimizing maintenance is crucial, alternators' lack of a commutator makes them a more attractive option.

- Cost: The initial cost and ongoing maintenance costs should be considered when choosing between the two types of devices.

Conclusion:

While both generators and alternators convert mechanical energy into electrical energy, the fundamental difference lies in their output current: DC for generators and AC for alternators. This difference leads to significant variations in their efficiency, maintenance requirements, power output capabilities, and suitability for different applications. Understanding these distinctions is key to selecting the appropriate device for any given power generation task. Choosing between a generator and alternator requires careful consideration of factors such as power needs, desired output current, maintenance budgets, and the overall complexity of the system. By understanding the nuances of each technology, you can ensure you select the optimal solution for your specific needs.

Latest Posts

Latest Posts

-

Shapes With 3 Lines Of Symmetry

May 09, 2025

-

Is 1 Cc The Same As 1 Ml

May 09, 2025

-

A Fully Loaded Slow Moving Freight Elevator

May 09, 2025

-

Is Potato A Root Or Stem Vegetable

May 09, 2025

-

Which Element Has The Least Metallic Character

May 09, 2025

Related Post

Thank you for visiting our website which covers about What Is Difference Between Generator And Alternator . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.