What Happens When A Gas Is Compressed

Juapaving

Mar 14, 2025 · 6 min read

Table of Contents

What Happens When a Gas is Compressed? A Deep Dive into Gas Compression

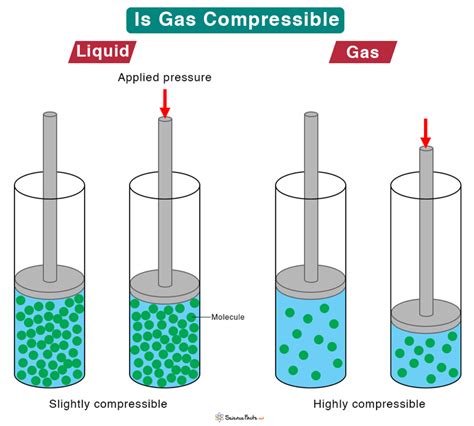

Understanding what happens when a gas is compressed is crucial across numerous scientific disciplines and engineering applications. From the simple act of inflating a bicycle tire to the complex processes within industrial refrigeration systems, gas compression plays a vital role. This comprehensive article will explore the multifaceted effects of compressing a gas, examining the underlying principles, associated changes, and practical applications.

The Fundamental Principles: Boyle's Law and Beyond

The behavior of gases under compression is primarily governed by gas laws, with Boyle's Law serving as a foundational principle. Boyle's Law states that at a constant temperature, the volume of a gas is inversely proportional to its pressure. This means that if you increase the pressure on a gas, its volume will decrease proportionally, and vice versa. This relationship is mathematically expressed as:

P₁V₁ = P₂V₂

Where:

- P₁ = initial pressure

- V₁ = initial volume

- P₂ = final pressure

- V₂ = final volume

However, Boyle's Law only holds true under ideal conditions, assuming the gas behaves ideally. Real gases deviate from ideal behavior, particularly at high pressures and low temperatures, due to intermolecular forces and the finite volume occupied by the gas molecules themselves.

Beyond Ideal Behavior: Real Gas Effects

When dealing with real gases, deviations from Boyle's Law become significant. These deviations are accounted for by considering factors such as:

- Intermolecular forces: Attractive forces between gas molecules cause them to clump together, reducing the effective volume available for expansion. This leads to a lower volume than predicted by Boyle's Law at a given pressure.

- Molecular volume: Gas molecules themselves occupy a finite volume, reducing the available space for expansion. This effect becomes more pronounced at high pressures.

- Temperature: Temperature significantly affects the kinetic energy of gas molecules. Higher temperatures lead to more energetic collisions and greater resistance to compression.

To accurately describe the behavior of real gases, more complex equations of state, such as the van der Waals equation, are employed. These equations incorporate correction factors to account for intermolecular forces and molecular volume.

Thermodynamic Changes During Compression

Compressing a gas is not merely a change in volume and pressure; it's a thermodynamic process involving changes in temperature, internal energy, and entropy. The exact nature of these changes depends on the conditions under which the compression occurs.

Adiabatic Compression: No Heat Exchange

Adiabatic compression occurs when no heat is exchanged between the gas and its surroundings during the compression process. This is often approximated in rapid compression processes where there's insufficient time for significant heat transfer. In adiabatic compression:

- Temperature increases: The work done on the gas during compression is converted into increased internal energy, leading to a rise in temperature.

- Entropy decreases: Because the process is rapid and prevents heat dissipation, the entropy of the gas decreases, making it a non-equilibrium process.

Isothermal Compression: Constant Temperature

Isothermal compression occurs when the temperature of the gas remains constant throughout the compression process. This requires controlled heat transfer to the surroundings, preventing temperature fluctuations. In isothermal compression:

- Pressure increases proportionally to the decrease in volume: The relationship between pressure and volume follows Boyle's Law more closely.

- Internal energy remains constant: Any increase in internal energy due to compression is balanced by heat transfer to the surroundings.

- Entropy changes: While the internal energy remains constant, the entropy of the gas still changes because the gas is doing work on the surroundings.

Isobaric Compression: Constant Pressure

Isobaric compression occurs when the pressure of the gas remains constant during compression. This typically involves a change in volume and temperature. In isobaric compression:

- Volume decreases: The gas is compressed at a constant pressure.

- Temperature changes: The temperature change depends on the heat transfer between the gas and its surroundings. The first law of thermodynamics dictates the relationship between work done, heat transfer, and internal energy change.

Practical Applications of Gas Compression

Gas compression is a fundamental process with numerous applications across various industries:

1. Refrigeration and Air Conditioning:

Refrigeration cycles rely on the compression and expansion of refrigerants to achieve cooling. Compression raises the refrigerant's temperature, allowing heat rejection to the surroundings, while expansion lowers the temperature, absorbing heat from the space to be cooled.

2. Industrial Processes:

Many industrial processes, such as chemical synthesis, petroleum refining, and natural gas processing, utilize gas compression to achieve desired pressures and flow rates. Compressors are essential for transporting and storing gases.

3. Pneumatic Systems:

Pneumatic tools and systems rely on compressed air to power machinery and actuators. The compressed air provides a clean, safe, and reliable source of energy for various applications.

4. Breathing Apparatus:

Scuba diving and other breathing apparatus rely on compressed air or other gases to provide breathable air at depth. The compression of these gases allows for compact storage and efficient delivery.

5. Transportation:

Compressed natural gas (CNG) is used as a fuel for vehicles, offering a cleaner alternative to gasoline. CNG requires efficient compression and storage systems for practical use.

Types of Compressors

Various types of compressors are designed to handle different gases and pressure requirements:

- Reciprocating compressors: These use pistons to compress gas in a cyclical motion. They are suitable for high-pressure applications but can be less efficient than other types.

- Rotary compressors: These use rotating components, such as screws or vanes, to compress gas. They are often more efficient and quieter than reciprocating compressors.

- Centrifugal compressors: These use rotating impellers to accelerate gas, increasing its pressure. They are suitable for high-volume, lower-pressure applications.

- Axial compressors: These use a series of rotating blades to compress gas along an axis. They are highly efficient for large-scale applications, such as jet engines.

The choice of compressor depends on factors such as the gas being compressed, desired pressure and flow rate, efficiency requirements, and cost considerations.

Safety Considerations in Gas Compression

Gas compression involves inherent risks, especially with high-pressure systems. Safety precautions are essential to prevent accidents and injuries. These include:

- Proper equipment selection and maintenance: Using appropriately sized and well-maintained equipment is crucial to prevent failures.

- Pressure relief valves: These devices prevent excessive pressure buildup by releasing gas if the pressure exceeds a safe limit.

- Leak detection and prevention: Regular inspection and maintenance are vital to detect and prevent leaks, which can lead to explosions or asphyxiation.

- Personal protective equipment (PPE): Workers handling high-pressure systems should always wear appropriate PPE, such as safety glasses, gloves, and hearing protection.

- Emergency procedures: Clear emergency procedures should be in place to handle unexpected events, such as equipment failures or leaks.

Conclusion

Gas compression is a fundamental process with far-reaching implications across numerous fields. Understanding the principles governing gas behavior under compression, the thermodynamic changes involved, and the practical applications of this process is vital for engineers, scientists, and anyone working with gases. The choice of compression technology and the implementation of robust safety measures are critical to ensure efficient and safe operation. By considering the nuances of real gas behavior and adhering to safety guidelines, we can harness the power of gas compression for countless beneficial applications.

Latest Posts

Latest Posts

-

Simplify The Square Root Of 160

Mar 14, 2025

-

How Many Lines Of Symmetry On A Square

Mar 14, 2025

-

What Is An Organized Collection Of Data

Mar 14, 2025

-

What Is The Prime Factor Of 68

Mar 14, 2025

-

Common Factors Of 27 And 45

Mar 14, 2025

Related Post

Thank you for visiting our website which covers about What Happens When A Gas Is Compressed . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.