What Are Factors That Affect Friction

Juapaving

Mar 22, 2025 · 6 min read

Table of Contents

What are Factors that Affect Friction? A Deep Dive into the Science of Surfaces

Friction, a force that resists motion between surfaces in contact, is a fundamental concept in physics with far-reaching implications across various fields. Understanding the factors affecting friction is crucial for engineers designing efficient machines, physicists modeling complex systems, and even everyday individuals navigating the world around them. This article delves deep into the science behind friction, exploring the numerous factors that influence its magnitude and nature.

The Basics of Friction: A Necessary Evil

Before exploring the intricacies of friction's influencing factors, let's establish a fundamental understanding of the force itself. Friction is fundamentally a consequence of the interaction between the surfaces of two objects. At a microscopic level, even seemingly smooth surfaces are rough, possessing irregularities and imperfections. When these surfaces come into contact, these irregularities interlock, creating resistance to motion.

There are two main types of friction:

-

Static Friction: This type of friction acts on objects at rest. It prevents the object from starting to move. The maximum static friction force is proportional to the normal force (the force pressing the surfaces together).

-

Kinetic (Sliding) Friction: This type of friction acts on objects that are already in motion. It opposes the motion of the object. Kinetic friction is generally less than the maximum static friction for the same surfaces.

Key Factors Influencing Friction: A Detailed Examination

Numerous factors can significantly influence the magnitude and characteristics of friction. Understanding these factors is critical for predicting and controlling frictional forces in various applications.

1. Nature of the Surfaces in Contact: The Microscopic Landscape

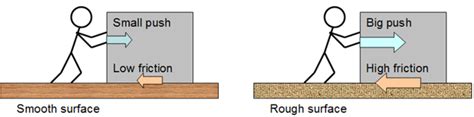

The texture and material composition of the surfaces in contact profoundly impact friction. Rougher surfaces have more points of contact, leading to increased interlocking and higher friction. Conversely, smoother surfaces exhibit less friction.

Material Properties: Different materials possess unique surface properties. For instance, rubber on asphalt exhibits significantly higher friction than steel on ice. This difference arises from variations in surface roughness, molecular interactions (adhesive forces), and the materials' inherent elasticity. The hardness of a material also plays a role; harder materials generally result in lower friction.

Consider the following:

-

Microscale roughness: Even polished surfaces exhibit microscopic irregularities. Advanced microscopy techniques reveal the complex topography of surfaces, highlighting the critical role of surface texture in friction.

-

Surface chemistry: The chemical composition of the surfaces involved affects the intermolecular forces between the surfaces. Materials with strong intermolecular attractions will exhibit higher friction.

-

Surface contamination: Dust, oils, or other contaminants present on the surfaces can significantly alter the frictional forces. These contaminants can fill in surface irregularities, reducing friction (lubrication), or they can create additional points of interaction, increasing friction.

2. The Normal Force: Pressing Down on the Problem

The normal force, the force perpendicular to the surfaces in contact, directly influences friction. A greater normal force means more significant pressure between the surfaces, leading to increased interlocking and stronger frictional forces. Think of pushing a heavy box across a floor versus a light box – the heavier box requires more force to overcome friction due to the larger normal force.

Understanding how normal force interacts with friction is crucial in many engineering applications. For example, in braking systems, the normal force applied to the brake pads against the rotor is critical in generating the necessary frictional force to slow down a vehicle.

3. Relative Speed: The Velocity Effect

While static friction is independent of speed, kinetic friction exhibits a complex relationship with relative speed. At low speeds, kinetic friction is often considered constant. However, at higher speeds, the relationship between friction and speed can become more intricate. Depending on the materials involved, friction might increase, decrease, or remain relatively constant with increasing speed. This speed-dependent behavior is particularly relevant in high-speed applications such as high-speed trains and Formula 1 racing cars.

The complexities of high-speed friction involve factors like:

-

Heat generation: At high speeds, the increased frictional forces lead to significant heat generation, which can alter the material properties of the surfaces, modifying the frictional behavior.

-

Surface deformation: High speeds can cause significant surface deformation, impacting the contact area and consequently the frictional force.

-

Lubricant behavior: Lubricants play a crucial role in high-speed applications, and their behaviour under high shear rates and temperature changes can significantly impact friction.

4. Temperature: Heating Things Up (or Down)

Temperature significantly affects the frictional behavior of materials. Generally, increasing the temperature can reduce friction in some materials, while increasing it in others. This is because temperature changes the material properties, such as viscosity, stiffness, and surface interactions. For instance, certain lubricants become less viscous at higher temperatures, reducing friction. Conversely, some materials might experience increased surface adhesion at higher temperatures, leading to higher friction.

5. Lubrication: Smoothing the Way

Lubrication is a powerful method of significantly reducing friction. Lubricants, typically liquids or greases, introduce a thin layer between the surfaces in contact, reducing direct interaction between the asperities (microscopic surface irregularities). This separation minimizes interlocking and consequently lowers friction. The effectiveness of a lubricant depends on its viscosity, chemical properties, and the operating conditions (temperature, pressure, speed).

Different types of lubrication include:

-

Fluid lubrication: A continuous film of lubricant separates the surfaces.

-

Boundary lubrication: A thin layer of lubricant adheres to the surfaces.

-

Solid lubrication: Solid materials, such as graphite or molybdenum disulfide, provide a lubricating layer.

6. Area of Contact (Apparent): A Misconception Clarified

Contrary to a common misconception, the apparent area of contact (the overall surface area of the objects) does not significantly affect the magnitude of friction. The frictional force is primarily determined by the real area of contact – the area where the surfaces actually touch at a microscopic level. While a larger apparent contact area might seem to suggest more friction, the real contact area remains relatively unchanged unless the normal force is altered.

Applications and Implications of Understanding Friction

The principles of friction are ubiquitous in various fields:

-

Mechanical Engineering: Understanding friction is essential in designing efficient machines, reducing wear and tear, and optimizing performance. In automotive engineering, for example, friction is crucial in braking systems, engine operation, and tire-road interaction.

-

Civil Engineering: Friction is critical in structural design, considering stability and load-bearing capacity. The interaction between soil and structures, for instance, is governed by frictional forces.

-

Biomechanics: Friction plays a significant role in human movement and joint function. Understanding frictional forces in the body is crucial in biomechanics research and prosthetics design.

-

Tribology: The science of tribology specifically studies friction, wear, and lubrication, providing a systematic framework for understanding and controlling frictional interactions.

Conclusion: A Continuing Exploration

The study of friction is an ongoing area of research. While we have a good understanding of the fundamental factors that influence friction, many aspects remain complex and require further investigation. As technology advances and we delve deeper into the nanoscale interactions of materials, our comprehension of friction will undoubtedly improve, leading to further advancements across various fields. This comprehensive understanding of friction is not merely academic; it is instrumental in designing better machines, optimizing processes, and addressing significant challenges across a wide range of disciplines. From minimizing energy loss in industrial machinery to improving the performance of athletic equipment, mastering friction continues to be a critical undertaking in engineering and scientific advancement.

Latest Posts

Latest Posts

-

Cuanto Es 15 Inches En Centimetros

May 09, 2025

-

The Least Common Multiple Of 12 And 8

May 09, 2025

-

Is 5 7 A Rational Number

May 09, 2025

-

How To Find Minors Of Matrix

May 09, 2025

-

This Is The Process Of Copying Dna To Rna

May 09, 2025

Related Post

Thank you for visiting our website which covers about What Are Factors That Affect Friction . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.