Two Stroke Engine Four Stroke Engine Difference

Juapaving

Mar 25, 2025 · 6 min read

Table of Contents

Two-Stroke vs. Four-Stroke Engines: A Comprehensive Comparison

Choosing the right engine for your application—whether it's a lawnmower, motorcycle, or something more industrial—requires understanding the fundamental differences between two-stroke and four-stroke engines. While both achieve the same basic goal—converting fuel into mechanical energy—they do so through vastly different processes. This detailed comparison will explore the key distinctions between these engine types, examining their operational principles, performance characteristics, environmental impact, and suitability for various applications.

Understanding the Fundamental Differences: Cycles and Power Strokes

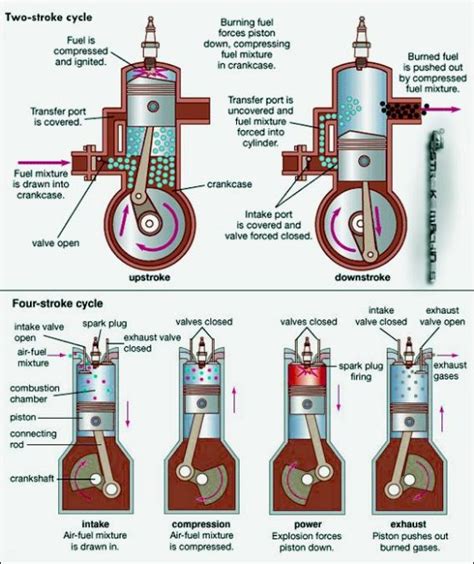

The core difference lies in the number of piston strokes required to complete one combustion cycle. A two-stroke engine completes one power stroke for every two piston strokes, while a four-stroke engine requires four piston strokes for a single power stroke. This seemingly simple difference has far-reaching implications for efficiency, power delivery, and overall design.

Two-Stroke Engine: The Rapid-Fire Cycle

In a two-stroke engine, the piston completes a single upward and downward movement to complete a combustion cycle. The intake and exhaust processes occur simultaneously via strategically placed ports in the engine cylinder. This allows for a simpler design with fewer moving parts, resulting in a smaller and lighter engine.

- Intake and Compression: As the piston moves upward, it compresses the fuel-air mixture already in the cylinder. Simultaneously, fresh fuel-air mixture enters through intake ports near the bottom of the cylinder.

- Power and Exhaust: As the piston reaches the top of its stroke, the spark plug ignites the compressed fuel-air mixture. The resulting explosion forces the piston downward, creating the power stroke. As the piston descends, exhaust ports are uncovered, allowing the spent gases to escape.

Four-Stroke Engine: The Precise and Efficient Cycle

The four-stroke engine, in contrast, executes a more controlled and sequential combustion cycle, involving four distinct piston strokes:

- Intake: As the piston moves downward, the intake valve opens, drawing a fresh fuel-air mixture into the cylinder.

- Compression: The piston then moves upward, compressing the fuel-air mixture. The intake valve closes during this stage.

- Power: At the top of the compression stroke, the spark plug ignites the mixture, forcing the piston downward. This is the power stroke.

- Exhaust: As the piston moves upward again, the exhaust valve opens, pushing the spent gases out of the cylinder. The exhaust valve then closes, preparing for the next intake stroke.

Comparing Key Performance Characteristics

While both engine types serve similar purposes, their performance characteristics differ significantly:

Power Output and Torque

Generally, four-stroke engines produce more power and torque at lower RPMs compared to their two-stroke counterparts. This smoother power delivery makes them ideal for applications requiring consistent power, such as cars and larger machinery. Two-stroke engines, while capable of high power output, often deliver it at higher RPMs and with a less consistent power curve. They excel in applications requiring bursts of power, like chainsaws and some motorcycles.

Fuel Efficiency

Four-stroke engines are significantly more fuel-efficient than two-stroke engines. This is primarily because they utilize a dedicated intake and exhaust system, allowing for better control of the air-fuel mixture and more complete combustion. Two-stroke engines, due to their simultaneous intake and exhaust processes, tend to lose unburned fuel and lubricating oil through the exhaust, resulting in lower efficiency and increased emissions.

Emissions

Two-stroke engines are notorious for their higher emissions of pollutants, including hydrocarbons and unburnt fuel. This is largely due to their less efficient combustion process and the mixing of oil with fuel, resulting in significant emissions of particulate matter. While advancements have reduced emissions, two-stroke engines still generally produce considerably more pollution than four-stroke engines. Four-stroke engines, benefiting from better combustion and separate lubrication systems, generate significantly fewer harmful emissions. Modern four-stroke engines, with advancements in fuel injection and exhaust after-treatment systems, have achieved remarkably low emission levels.

Maintenance

Two-stroke engines generally require more frequent maintenance. Because the lubricating oil is mixed with the fuel, the engine components are subjected to more wear and tear. Regular oil changes aren't as straightforward, as the oil needs to be topped off regularly and changed based on usage. Four-stroke engines, with their separate lubrication systems, require less frequent maintenance, offering longer intervals between oil changes and requiring less overall maintenance.

Weight and Size

Two-stroke engines are typically lighter and more compact than four-stroke engines of comparable power output. This is attributed to their simpler design, with fewer moving parts. This makes them well-suited for portable equipment and applications where size and weight are critical factors. Four-stroke engines, due to their more complex design, tend to be heavier and larger, though advancements in materials and manufacturing techniques have reduced this difference.

Noise and Vibration

Two-stroke engines tend to be noisier and vibrate more than four-stroke engines. Their simpler design and the less controlled combustion process contribute to higher noise levels and vibrations. Modern four-stroke engines, with advancements in noise reduction techniques, are significantly quieter and smoother in operation.

Cost

Two-stroke engines are generally less expensive to manufacture than four-stroke engines. Their simpler design and fewer parts lead to lower production costs, making them a cost-effective option for many applications. While initial costs might be lower, the ongoing cost of maintenance and fuel consumption should be considered. Four-stroke engines, while more expensive upfront, can offer long-term cost savings due to improved fuel efficiency and lower maintenance requirements.

Applications: Where Each Engine Type Shines

The choice between a two-stroke and a four-stroke engine depends heavily on the specific application.

Two-Stroke Engine Applications

- Chainsaws: Their high power-to-weight ratio is ideal for demanding cutting tasks.

- Outboard motors (smaller models): Lightweight and compact, suited for smaller boats.

- Motorcycles (certain models): High RPM power is favored in certain racing and off-road applications.

- Model airplanes and boats: The combination of high power and lightweight construction is advantageous.

- Lawn equipment (some models): Simple, compact, and inexpensive.

Four-Stroke Engine Applications

- Automobiles: The preferred choice for cars and trucks due to efficiency, power, and lower emissions.

- Trucks and heavy machinery: High torque at low RPMs is essential for hauling and heavy-duty applications.

- Lawnmowers (many models): Fuel efficiency and lower noise levels are highly desirable for residential use.

- Motorcycles (many models): Smoother power delivery and improved fuel economy are valued.

- Outboard motors (larger models): More power and torque are needed for larger boats.

The Future of Two-Stroke and Four-Stroke Engines

While four-stroke engines have largely superseded two-stroke engines in many applications due to their superior efficiency and lower emissions, two-stroke technology continues to evolve. Advancements in direct fuel injection and other technologies are addressing the environmental concerns, making two-stroke engines cleaner and more efficient. However, four-stroke engines are likely to remain the dominant choice for most applications due to their inherent advantages in terms of efficiency, power delivery, and environmental impact. The future may see a niche role for two-stroke engines where lightweight and compact size is paramount and emissions regulations are less stringent.

Conclusion: Choosing the Right Engine

The decision of whether to choose a two-stroke or four-stroke engine is not a simple one. A careful consideration of the specific application requirements, including power needs, fuel efficiency, emissions standards, maintenance requirements, and cost factors is crucial. While four-stroke engines offer superior performance and efficiency in many applications, two-stroke engines retain their relevance in situations where lightweight construction, compact size, and low initial cost are paramount. Understanding these differences allows for informed decision-making, leading to optimal engine selection for any given application.

Latest Posts

Latest Posts

-

What Is The Prime Factorization Of 53

Mar 26, 2025

-

How Many Electrons In Double Bond

Mar 26, 2025

-

What Is The Multiples Of 13

Mar 26, 2025

-

How Do You Find The Relative Abundance

Mar 26, 2025

-

What Are The Factors For 86

Mar 26, 2025

Related Post

Thank you for visiting our website which covers about Two Stroke Engine Four Stroke Engine Difference . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.