The Strength Of An Electromagnet Is Primarily Proportional To Its

Juapaving

Mar 10, 2025 · 6 min read

Table of Contents

The Strength of an Electromagnet is Primarily Proportional to its: A Deep Dive into Electromagnetic Principles

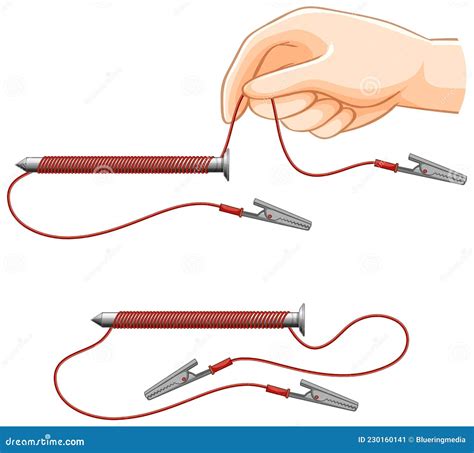

Electromagnets, those fascinating devices that harness the power of electricity to create magnetism, are ubiquitous in modern technology. From hard drives and MRI machines to scrapyard cranes and electric motors, their applications are vast and varied. Understanding the factors that govern the strength of an electromagnet is crucial for designing and optimizing these devices. This comprehensive guide delves deep into the physics behind electromagnets, exploring the primary factors influencing their magnetic field strength. We will explore the relationship between these factors, explaining how adjustments impact the overall strength and functionality of the electromagnet.

The Core Relationship: Current, Turns, and Core Material

The strength of an electromagnet is primarily proportional to three key factors:

- The current (I) flowing through the coil: A higher current leads to a stronger magnetic field. This is a fundamental principle of electromagnetism; the greater the flow of charge, the more intense the magnetic field it generates.

- The number of turns (N) in the coil: More turns of wire amplify the magnetic field. Each turn contributes to the overall magnetic field, resulting in a cumulative effect. Think of it like stacking many individual magnets – the combined effect is significantly stronger.

- The permeability (µ) of the core material: The core material plays a crucial role in concentrating and enhancing the magnetic field. Materials with high permeability, such as iron, significantly increase the magnetic field strength compared to air-core electromagnets.

These three factors are mathematically related through the equation for the magnetic field strength (B) of a solenoid (a common type of electromagnet):

B = µ₀µᵣNI/l

Where:

- B represents the magnetic flux density (often measured in Teslas).

- µ₀ is the permeability of free space (a constant).

- µᵣ is the relative permeability of the core material (a measure of how much better the material concentrates the magnetic field compared to free space).

- N is the number of turns in the coil.

- I is the current flowing through the coil.

- l is the length of the solenoid.

This equation highlights the directly proportional relationship between the magnetic field strength (B) and the current (I) and number of turns (N). Increasing either I or N will directly increase B, provided other factors remain constant. The core material's permeability (µᵣ) acts as a multiplicative factor, significantly amplifying the magnetic field strength.

Deeper Dive into Each Factor:

1. Current (I): The Driving Force

The current flowing through the coil is the fundamental source of the magnetic field. Electrons moving through the wire create a magnetic field around each segment of the wire. When these segments are wound into a coil, the individual magnetic fields combine to produce a significantly stronger, concentrated field. Increasing the current increases the number of moving electrons, directly increasing the magnetic field strength. However, there are practical limitations. Increasing the current beyond a certain point can lead to overheating of the wire, potentially damaging the electromagnet or even causing a fire. Proper heat dissipation mechanisms are crucial for high-current applications.

2. Number of Turns (N): Amplifying the Effect

The number of turns in the coil is another crucial factor. Each turn of wire adds to the overall magnetic field strength. Increasing the number of turns effectively increases the total length of the wire through which the current flows, resulting in a more powerful magnetic field. However, there is a practical limit to the number of turns due to factors like space constraints and increased resistance in the wire. More turns mean a longer wire, leading to higher resistance and potentially lower overall efficiency if the current supply can't compensate for the increased resistance.

3. Core Material (µ): The Magnetic Amplifier

The core material's permeability plays a pivotal role in determining the electromagnet's strength. A high-permeability material like iron, nickel, or certain ferrite alloys concentrates the magnetic flux lines, effectively amplifying the magnetic field generated by the coil. This is because these materials have a high density of magnetic domains that readily align with the applied magnetic field, significantly increasing the overall magnetic flux density. In contrast, an air-core electromagnet has a much weaker magnetic field due to the low permeability of air. Choosing the right core material is critical for optimizing the electromagnet's strength and efficiency for a particular application. Different core materials exhibit different saturation points – beyond which further increase in current will not significantly increase the magnetic field strength.

Beyond the Basics: Other Influencing Factors

While current, turns, and core material are the primary factors, several other elements influence an electromagnet's strength:

- Coil Geometry: The shape and size of the coil significantly impact the magnetic field distribution. A solenoid (cylindrical coil) produces a relatively uniform field inside, while other coil configurations may generate different field patterns. The coil's length and diameter influence the strength and distribution of the magnetic field.

- Coil Winding Technique: The way the wire is wound onto the core affects the overall strength and uniformity of the magnetic field. Tight, even winding is crucial for maximizing the magnetic field strength.

- Air Gaps: Any air gap in the magnetic circuit reduces the overall magnetic field strength. Minimizing air gaps in the core is essential for creating a strong and efficient electromagnet.

- Temperature: The magnetic properties of core materials are temperature-dependent. Changes in temperature can affect the permeability and thus the strength of the electromagnet.

- Frequency of Current: For alternating current (AC) electromagnets, the frequency of the current influences the magnetic field strength due to factors like skin effect and hysteresis losses in the core material. Higher frequencies can lead to reduced efficiency.

Applications and Considerations: Putting it All Together

The principles discussed above are essential for designing and using electromagnets effectively. Consider the following applications and how the factors discussed influence performance:

- Lifting Magnets: These are designed for heavy-duty applications, requiring high magnetic field strength. Large currents, many turns, and high-permeability cores are employed to achieve the required lifting force.

- Electric Motors: The strength of the electromagnets in motors determines the torque and speed. Careful consideration of coil geometry, core material, and current is critical for optimal motor performance.

- Magnetic Resonance Imaging (MRI) Machines: These require incredibly powerful and uniform magnetic fields. Superconducting magnets are often employed to achieve the necessary field strength while minimizing energy loss.

- Hard Disk Drives: Small, precise electromagnets are used to write and read data on hard drives. The magnetic field strength must be carefully controlled to ensure accurate data storage and retrieval.

Conclusion: A Powerful Combination

The strength of an electromagnet is a function of the interplay between current, number of turns, and core material permeability. Understanding this fundamental relationship is vital for designing and utilizing electromagnets effectively in diverse applications. While the equation B = µ₀µᵣNI/l provides a simplified representation, the practical implementation requires careful consideration of various factors like coil geometry, winding technique, air gaps, temperature, and frequency of the current. Optimizing these parameters ensures the efficient and robust performance of electromagnets in a wide range of technological systems. Further exploration into specific material properties and advanced coil designs can lead to significant improvements in electromagnet performance and opens avenues for innovation in various technological fields. By carefully considering and optimizing all relevant factors, engineers and scientists can harness the full potential of electromagnets to create powerful and efficient devices for countless applications.

Latest Posts

Latest Posts

-

Is Sound Potential Or Kinetic Energy

Mar 10, 2025

-

Is 34 A Prime Number Or A Composite Number

Mar 10, 2025

-

Which Of The Following Lists Disadvantages Of Nuclear Power

Mar 10, 2025

-

Place The Following Parts Of A Reflex Arc In Order

Mar 10, 2025

-

Five Letter Word That Ends With Er

Mar 10, 2025

Related Post

Thank you for visiting our website which covers about The Strength Of An Electromagnet Is Primarily Proportional To Its . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.