Rusting Of Iron Is A Chemical Change True Or False

Juapaving

Mar 30, 2025 · 5 min read

Table of Contents

Rusting of Iron: A Definitive Guide to Chemical Change

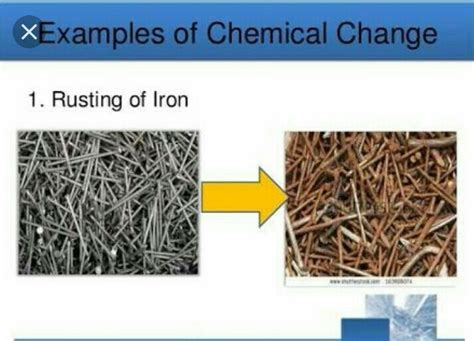

The statement "Rusting of iron is a chemical change" is unequivocally true. Rusting isn't merely a superficial alteration; it's a fundamental transformation of iron's chemical composition, a process impossible to reverse simply by physical means. This article will delve deep into the science behind rust formation, exploring the chemical reactions involved, the factors influencing the rate of rusting, and dispelling common misconceptions.

Understanding Chemical Change vs. Physical Change

Before we dissect the rusting process, let's establish a clear understanding of the difference between chemical and physical changes.

-

Physical Change: A physical change alters the form or appearance of a substance without changing its chemical composition. Examples include melting ice (water changes from solid to liquid), breaking a glass (glass changes shape), or dissolving sugar in water (sugar disperses but remains sugar). These changes are often reversible.

-

Chemical Change: A chemical change, also known as a chemical reaction, involves the rearrangement of atoms and molecules to form new substances with different properties. These changes are often irreversible and are accompanied by observable signs like a change in color, temperature, or the formation of a gas or precipitate. Burning wood, cooking an egg, and rusting iron are all examples of chemical changes.

The Chemistry of Rust: Oxidation and Reduction

Rust, chemically known as iron(III) oxide-hydrate (Fe₂O₃·nH₂O), is the result of a redox reaction, specifically an oxidation-reduction reaction. This means that electrons are transferred between atoms. Iron atoms lose electrons (oxidation) and oxygen atoms gain electrons (reduction). This process requires the presence of both oxygen (O₂) and water (H₂O).

The Reaction: A Step-by-Step Breakdown

The rusting process is complex and doesn't follow a single, straightforward equation. However, we can simplify the overall reaction as follows:

4Fe(s) + 3O₂(g) + 6H₂O(l) → 4Fe(OH)₃(s)

This equation shows iron (Fe) reacting with oxygen (O₂) and water (H₂O) to form iron(III) hydroxide (Fe(OH)₃), a hydrated form of iron(III) oxide, which is rust. However, this is a simplified representation. The actual process involves several intermediate steps and can lead to a variety of iron oxides and hydroxides.

The Role of Electrolyte Solutions: Enhancing the Reaction

The presence of an electrolyte, such as salt (NaCl) dissolved in water, significantly accelerates the rusting process. Electrolytes provide ions that enhance the conductivity of the solution, facilitating the flow of electrons during the redox reaction. This is why cars rust faster in coastal areas or during winter when roads are salted.

Evidence of Chemical Change in Rusting

Several key observations confirm that rusting is a chemical change:

-

Color Change: Iron is a silvery-gray metal, while rust is a reddish-brown substance. This dramatic color shift is a strong indicator of a chemical transformation.

-

Formation of a New Substance: Rust is a different substance from iron. It has different chemical properties, such as being brittle and porous, unlike the relatively strong and dense iron. You cannot simply "un-rust" iron and revert it to its original state.

-

Irreversibility: Rust formation is an irreversible process. While you can remove rust, you cannot simply reverse the chemical reaction to restore the original iron. Removing rust often involves mechanical methods (scraping, sanding) or chemical treatments.

-

Energy Change: Although the heat released during rusting is not readily noticeable, it is a slightly exothermic process, meaning it releases a small amount of heat. This energy change is characteristic of chemical reactions.

Factors Affecting the Rate of Rusting

Several environmental factors influence how quickly iron rusts:

-

Oxygen Availability: The presence of oxygen is essential for rusting. The more oxygen available, the faster the rusting process.

-

Water Content: Water acts as a medium for the electrochemical reactions involved in rusting. The higher the humidity or the presence of standing water, the faster the rusting.

-

Acidity: Acidic environments accelerate rusting. The presence of acids increases the rate of electron transfer during the redox reaction.

-

Temperature: Higher temperatures generally increase the rate of chemical reactions, including rusting.

-

Presence of Electrolytes: As mentioned earlier, the presence of electrolytes like salt increases the conductivity of the solution, speeding up the electron transfer and accelerating rusting.

-

Surface Area: A larger surface area of iron exposed to the environment will lead to faster rusting. This is why iron in powdered form rusts much faster than a solid piece of iron.

Preventing Rust: Protective Measures

Understanding the chemistry of rusting allows us to develop strategies to prevent or slow down the process. Common methods include:

-

Protective Coatings: Painting, galvanizing (coating with zinc), or using other protective coatings create a barrier between the iron and the environment, preventing oxygen and water from reaching the iron surface.

-

Alloying: Adding other elements to iron, like chromium (in stainless steel), alters its chemical properties, making it less susceptible to rusting.

-

Cathodic Protection: This method involves connecting the iron to a more active metal (like zinc or magnesium), which acts as a sacrificial anode, preventing the iron from oxidizing.

Dispelling Common Misconceptions about Rusting

Several misconceptions surround the rusting process. Let’s address some of them:

-

Rust is just dirt: Rust is not simply dirt accumulating on the surface. It is a chemical compound formed by a reaction between iron, oxygen, and water.

-

Rusting only happens in wet conditions: While water is essential for rusting, even in dry conditions, a small amount of moisture in the air is enough to initiate the process, albeit at a slower rate.

-

Rusting is a purely surface phenomenon: Rusting begins on the surface but can penetrate deep into the metal, compromising its structural integrity over time.

-

Once rusted, iron is permanently damaged: While rust cannot be easily reversed, it can be removed through mechanical or chemical means. However, this often leaves the underlying iron weakened.

Conclusion: Rusting – A Chemical Reality

The rusting of iron is undeniably a chemical change. It's a complex process involving a redox reaction, the formation of new substances with different properties, and irreversibility. By understanding the chemistry involved and the factors influencing the rate of rusting, we can develop effective methods for preventing this common yet significant form of metal degradation. The implications of rust are far-reaching, impacting infrastructure, vehicles, and countless other applications. Therefore, a thorough understanding of this chemical phenomenon is crucial in various fields. From designing corrosion-resistant materials to developing preventative measures, the ongoing research and development in this area are vital for mitigating the economic and societal impact of rust.

Latest Posts

Latest Posts

-

What Is The Lcm For 5 6 7

Apr 01, 2025

-

Difference Between Woody And Herbaceous Plants

Apr 01, 2025

-

Why Is Burning A Chemical Change

Apr 01, 2025

-

How Many Years Are In One Millennia

Apr 01, 2025

-

Whats The Difference Between Electron Geometry And Molecular Geometry

Apr 01, 2025

Related Post

Thank you for visiting our website which covers about Rusting Of Iron Is A Chemical Change True Or False . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.