How To Make The Strongest Electromagnet

Juapaving

Mar 25, 2025 · 6 min read

Table of Contents

How to Make the Strongest Electromagnet: A Comprehensive Guide

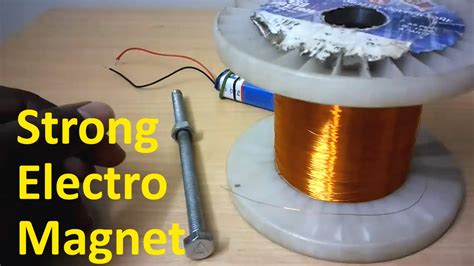

Creating a powerful electromagnet is a fascinating project blending physics and engineering. Whether you're a science enthusiast, a student, or an engineer, understanding the principles and techniques involved is crucial to building a truly effective electromagnet. This comprehensive guide will walk you through the process, detailing the factors that influence its strength and providing practical tips for optimization.

Understanding the Fundamentals of Electromagnetism

Before diving into the construction, let's establish the foundational principles. An electromagnet's strength, measured in Tesla (T) or Gauss (G), depends primarily on three factors:

1. The Number of Turns (N):

The more coils of wire you wrap around the core, the stronger the magnetic field. Each loop adds to the overall magnetic flux, directly increasing the magnetic field strength. This is a fundamental relationship: a higher number of turns leads to a stronger magnet.

2. The Current (I):

The current flowing through the wire is another critical element. A higher current translates to a stronger magnetic field. This is directly proportional: double the current, roughly double the field strength (within certain limits). The current is limited by the wire's gauge and the power supply's capacity.

3. The Core Material (µ):

The core material plays a significant role in concentrating and amplifying the magnetic field. Materials with high magnetic permeability, like iron, nickel, and certain alloys, greatly enhance the electromagnet's strength. These materials readily allow magnetic flux lines to pass through them, focusing the field. Air, in contrast, has a permeability close to 1, resulting in a much weaker magnetic field for the same number of turns and current.

The Equation: Quantifying Electromagnet Strength

The relationship between these three factors is encapsulated in Ampère's Law, which, in its simplified form for a solenoid (a type of electromagnet), can be expressed as:

B = μ₀ * μr * N * I / L

Where:

- B represents the magnetic field strength (Tesla)

- μ₀ is the permeability of free space (a constant)

- μr is the relative permeability of the core material (a dimensionless quantity)

- N is the number of turns in the coil

- I is the current (Amperes)

- L is the length of the solenoid (meter)

This equation highlights the direct proportionality between magnetic field strength and the number of turns and the current. It also emphasizes the crucial role of the core material through its relative permeability.

Choosing the Right Materials and Components

Building a powerful electromagnet requires careful selection of materials:

1. The Core:

- Soft Iron: This is an excellent choice due to its high permeability and low hysteresis (residual magnetism after the current is switched off). It readily accepts and releases magnetic flux, allowing for efficient operation and quick demagnetization.

- Steel: While readily available, steel has higher hysteresis than soft iron, meaning it retains some magnetism even after the current is turned off. This can be advantageous in certain applications, but it reduces efficiency for a purely electromagnet.

- Ferrite: Ferrite cores are also a viable option, especially in high-frequency applications. They offer good permeability and are relatively inexpensive. However, their saturation point (the maximum magnetic field they can handle) is typically lower than iron cores.

- Shape Considerations: The shape of the core significantly impacts field strength and distribution. A cylindrical core provides a relatively uniform field along its axis, while other shapes can focus the field in specific ways.

2. The Wire:

- Gauge: The wire gauge determines the current carrying capacity. Thicker wires (lower gauge numbers) can handle higher currents without overheating. However, they are more challenging to wind tightly.

- Insulation: Properly insulated wire is crucial for safety and to prevent short circuits. Enamel-coated wire is commonly used in electromagnet construction.

- Length: The length of the wire will influence resistance. A longer wire means higher resistance, leading to increased heat generation and potential power losses. For maximum efficiency, strive for short, thick wire lengths if possible.

3. The Power Supply:

- Current Capacity: Ensure your power supply can deliver the required current without overloading. Electromagnets can draw significant amounts of current, especially those with many turns and thick wire.

- Voltage: The voltage of the power supply should be appropriate for the resistance of the wire. Using a voltage that’s too high can lead to overheating and damage.

The Construction Process: A Step-by-Step Guide

Constructing a strong electromagnet is a hands-on process. Here's a detailed guide:

-

Prepare the Core: Select your core material (soft iron is recommended for maximum strength). Ensure it's clean and free of any coatings that might interfere with the windings. Shape the core into a cylinder or other desired form.

-

Wind the Coil: Carefully and tightly wind the insulated wire around the core. Maintaining consistent spacing is crucial for optimal performance. Use a winding jig or other tool to help maintain even turns. More turns generally means a stronger magnet, but be mindful of the heat generated.

-

Secure the Coil: Once the desired number of turns is achieved, securely fasten the ends of the wire to prevent unraveling. You can use epoxy resin or other strong adhesive to solidify the coil.

-

Connect to a Power Supply: Connect the ends of the wire to your power supply, ensuring proper polarity. Use a multimeter to monitor the current flowing through the coil. Avoid overloading the power supply or exceeding the safe current of your wires.

-

Testing and Optimization: Once the circuit is complete, carefully test the magnet's strength. You can use a compass or a small ferrous object to assess the field's strength and uniformity. Observe the core's temperature – overheating can damage the components.

-

Refinement and Iteration: Based on your testing results, you can refine your design. You might adjust the number of turns, the current, or experiment with different core materials to maximize the magnet’s strength. Keep a detailed log of your experiments, noting the variables and their impact on field strength.

Safety Precautions: Handling Electromagnets Responsibly

Working with electromagnets, especially high-power ones, requires adherence to safety measures:

- Eye Protection: Wear safety glasses to protect your eyes from potential sparks or flying debris.

- Insulation: Ensure the wiring is properly insulated to prevent electrical shocks.

- Heat Management: Electromagnets generate heat during operation. Allow sufficient time for cooling and use appropriate heat sinks if needed.

- Overcurrent Protection: Use fuses or circuit breakers to protect against overcurrent conditions.

- Magnetic Field Awareness: Strong magnetic fields can affect sensitive electronic devices and pacemakers. Maintain a safe distance and avoid exposure to strong magnetic fields unnecessarily.

Advanced Techniques and Considerations

For those seeking even stronger electromagnets, consider these advanced techniques:

- Using Multiple Coils: Combining several coils can significantly increase the overall magnetic field strength. This is often employed in sophisticated electromagnet designs.

- Core Material Optimization: Experimenting with different core materials and shapes to find the optimal combination for your specific application.

- Cooling Systems: Implementing cooling systems, such as water cooling, can allow for higher currents and thus stronger magnetic fields by dissipating the generated heat more effectively.

- Electromagnet Design Software: Utilizing specialized software can facilitate modeling and optimization of your electromagnet’s design before physical construction.

Conclusion

Building a strong electromagnet is a rewarding endeavor that combines theoretical understanding with practical skill. By carefully selecting materials, adhering to proper construction techniques, and understanding the principles governing electromagnetism, you can create a powerful and efficient electromagnet for your needs. Remember always to prioritize safety and conduct thorough testing throughout the process. The information in this guide provides a robust foundation for your project. Experimentation and continuous refinement are key to achieving optimal results in building the strongest electromagnet possible.

Latest Posts

Latest Posts

-

What Is 25 Cm In Inches

Mar 26, 2025

-

Which Of The Following Statements Describes The Process Of Globalization

Mar 26, 2025

-

What Are The Greatest Common Factors Of 48

Mar 26, 2025

-

The Unit Of Energy In S I Units Is

Mar 26, 2025

-

How Does Temperature Relate To Kinetic Energy

Mar 26, 2025

Related Post

Thank you for visiting our website which covers about How To Make The Strongest Electromagnet . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.