Friction Always Works Blank The Direction Of Velocity

Juapaving

Mar 30, 2025 · 6 min read

Table of Contents

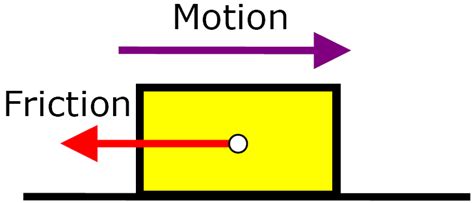

Friction Always Works Opposite the Direction of Velocity

Friction, a fundamental force in physics, is often described as a resisting force that opposes motion. However, a more precise definition states that friction always works opposite the direction of velocity. This seemingly simple statement underpins a wide range of phenomena, from the ease of walking to the complexities of designing high-speed vehicles. Understanding this principle is crucial for comprehending various aspects of mechanics and engineering. This article will delve deep into the nature of friction, exploring its different types, the factors influencing its magnitude, and its implications across diverse applications.

Understanding Friction: A Deeper Dive

Friction arises from the interaction between surfaces at the microscopic level. While macroscopic surfaces may appear smooth, at a microscopic scale they are rough, possessing irregularities and imperfections. When two surfaces come into contact, these irregularities interlock, creating resistance to relative motion. This resistance manifests as frictional force. The direction of this frictional force is always opposite to the direction of the relative velocity between the surfaces.

Types of Friction

Several types of friction exist, each with its own characteristics:

-

Static Friction: This is the frictional force that prevents two surfaces from moving relative to each other when a force is applied. It's the force you need to overcome to start an object moving. Static friction is self-adjusting, meaning it increases to match the applied force until it reaches its maximum value, known as the maximum static frictional force. Once this maximum is exceeded, the object begins to move.

-

Kinetic Friction (Sliding Friction): Once an object starts moving, the type of friction changes to kinetic friction. This force opposes the motion of an object already in motion. Kinetic friction is generally less than the maximum static friction for the same surfaces.

-

Rolling Friction: This type of friction occurs when an object rolls over a surface. It is significantly smaller than sliding friction, which explains why rolling objects are easier to move than sliding objects. This is due to the deformation of both the rolling object and the surface it rolls upon.

-

Fluid Friction: This is the resistance experienced by an object moving through a fluid (liquid or gas). It is dependent on factors like the object's shape, velocity, and the viscosity of the fluid. Fluid friction is a crucial factor in many applications, from designing airplanes to understanding blood flow in the human body.

Factors Affecting Frictional Force

The magnitude of frictional force is influenced by several factors:

-

Nature of the surfaces: The roughness of the surfaces involved plays a critical role. Rougher surfaces generally exhibit higher friction than smoother surfaces. The material composition of the surfaces also significantly impacts friction. For instance, wood on wood has a higher coefficient of friction than steel on ice.

-

Normal force: The normal force is the force exerted by a surface perpendicular to the contact surface. The greater the normal force, the greater the frictional force. This is because a higher normal force increases the number of microscopic interactions between the surfaces.

-

Coefficient of friction: The coefficient of friction (μ) is a dimensionless constant that represents the ratio of frictional force to the normal force. It varies depending on the materials involved and the type of friction (static or kinetic). It's an empirical value obtained through experimentation.

The relationship between frictional force (F<sub>f</sub>), coefficient of friction (μ), and normal force (N) is expressed by the following equation:

F<sub>f</sub> = μN

This equation holds true for both static and kinetic friction, but different coefficients are used for each. μ<sub>s</sub> represents the coefficient of static friction, and μ<sub>k</sub> represents the coefficient of kinetic friction.

Implications of Friction: Examples in Various Applications

The principle that friction always opposes the direction of velocity has far-reaching consequences in various fields:

Transportation:

-

Vehicle braking: The braking system in vehicles relies heavily on friction. The brake pads exert a force on the rotating wheels, creating friction that converts kinetic energy into heat, slowing the vehicle down. The direction of this frictional force is always opposite the direction of the wheels' rotation.

-

Tire traction: The friction between tires and the road surface enables vehicles to move forward and to turn. The tires push backward against the road, and the road pushes forward on the tires, resulting in forward motion. The friction force always acts opposite the direction of the tire’s slippage.

-

Aerodynamic drag: At high speeds, aerodynamic drag becomes a significant source of friction, opposing the movement of vehicles through the air. Designing vehicles with streamlined shapes helps minimize this drag and improve fuel efficiency.

Everyday Life:

-

Walking: Walking is possible because of the friction between your shoes and the ground. You push backward on the ground, and the ground pushes forward on your shoes, propelling you forward. The frictional force acts in the opposite direction to your intended movement.

-

Writing: The friction between the pen and paper allows the ink to transfer from the pen to the paper. Without friction, the pen would simply slide across the paper without leaving a mark.

-

Gripping objects: Holding onto objects is possible due to friction. The friction between your fingers and the object prevents it from slipping from your grasp.

Manufacturing and Engineering:

-

Lubrication: Lubricants are used to reduce friction between moving parts in machinery. By reducing friction, lubricants decrease wear and tear, improve efficiency, and extend the lifespan of machines.

-

Wear and tear: Friction is a major cause of wear and tear in mechanical systems. The constant rubbing of surfaces against each other leads to degradation and damage. Engineers employ various techniques to minimize this wear and tear, including using lubricants, choosing appropriate materials, and designing components to minimize contact stress.

-

Brakes and clutches: These mechanical components rely on frictional forces to function. The friction generated allows for controlled slowing down or stopping of rotating parts. The design of these components carefully balances the need for sufficient friction with the requirement to manage heat generation.

Advanced Concepts and Further Exploration

The study of friction is not limited to the simple models discussed above. More complex scenarios involve:

-

Friction in non-Newtonian fluids: Non-Newtonian fluids exhibit complex behavior that deviates from the simple relationship between shear stress and shear rate seen in Newtonian fluids. This complicates the analysis of friction in these materials.

-

Friction at nanoscale: At the nanoscale, friction behaves differently from macroscopic friction. Quantum mechanical effects and surface interactions become crucial factors.

-

Tribology: Tribology is the science and engineering of interacting surfaces in relative motion. It encompasses the study of friction, wear, and lubrication. This field seeks to optimize systems and minimize energy loss due to friction.

-

Modeling friction: Accurate modeling of friction is crucial for simulations in various engineering disciplines. However, it is a challenging task because of the complex nature of friction and the dependency on various interacting parameters. Sophisticated numerical methods and computational techniques are often employed.

Conclusion

Friction, while often perceived as a nuisance, is a fundamental force that plays a crucial role in numerous aspects of our daily lives and across various technological applications. The principle that friction always works opposite the direction of velocity is a cornerstone of understanding its behavior and its implications. From the simple act of walking to the sophisticated design of high-speed vehicles, friction’s influence is undeniable. By understanding its different types, the factors affecting its magnitude, and its diverse applications, we can better appreciate its significance and harness its power for innovation and progress. Further exploration into the advanced concepts and ongoing research in tribology continues to refine our understanding and ability to manage this fundamental force.

Latest Posts

Latest Posts

-

Least Common Multiple 12 And 18

Apr 01, 2025

-

What Phase Is The Reverse Of Prophase

Apr 01, 2025

-

Is Tungsten A Metal Or Nonmetal

Apr 01, 2025

-

How Many Seconds Is 24 Hours

Apr 01, 2025

-

What Is The Function Of The Collecting Duct

Apr 01, 2025

Related Post

Thank you for visiting our website which covers about Friction Always Works Blank The Direction Of Velocity . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.