Chemical Reaction Of Iron And Water

Juapaving

Mar 18, 2025 · 5 min read

Table of Contents

The Chemical Reaction of Iron and Water: A Deep Dive into Rust and Corrosion

Iron and water. Two seemingly innocuous substances, yet their interaction forms the basis of a ubiquitous and costly process: rust. Understanding the chemical reaction between iron and water is crucial in a multitude of fields, from preventing structural damage to developing advanced materials. This article delves deep into the intricate chemistry behind rust formation, exploring the factors that influence it and the methods employed to mitigate its effects.

The Basics: Oxidation and Reduction

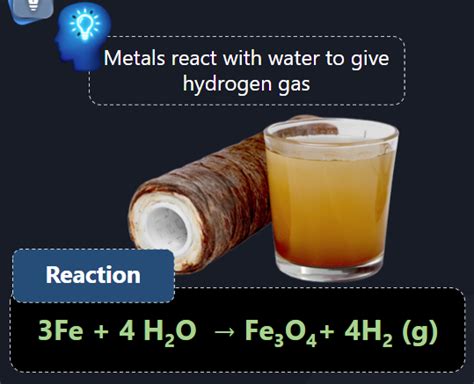

At the heart of the iron-water reaction lies the principle of oxidation-reduction, or redox reactions. These reactions involve the transfer of electrons between atoms. In the case of iron and water, iron (Fe) undergoes oxidation, losing electrons, while water (H₂O) or more accurately, the dissolved oxygen (O₂) in water, acts as the oxidizing agent, gaining electrons.

Iron's Oxidation: The Loss of Electrons

Iron, in its elemental form, possesses a relatively high reactivity. This means it readily loses electrons to achieve a more stable electronic configuration. In the presence of water and oxygen, iron atoms lose electrons, transforming from their neutral state (Fe) to a positively charged ion (Fe²⁺ or Fe³⁺). This process is represented by the following half-reactions:

- Fe → Fe²⁺ + 2e⁻ (Iron loses two electrons to form a ferrous ion)

- Fe → Fe³⁺ + 3e⁻ (Iron loses three electrons to form a ferric ion)

The ferrous ion (Fe²⁺) is further oxidized to the ferric ion (Fe³⁺) under most environmental conditions.

Water's Role: The Oxidizing Agent

Water itself is not directly involved in the initial oxidation of iron. Instead, the dissolved oxygen in water acts as the primary oxidizing agent. Oxygen molecules (O₂) readily accept the electrons released by iron, undergoing reduction to form hydroxide ions (OH⁻). This process can be represented by the half-reaction:

- O₂ + 2H₂O + 4e⁻ → 4OH⁻ (Oxygen gains four electrons and combines with water to form hydroxide ions)

The Formation of Rust: A Complex Process

The interaction between oxidized iron ions (Fe²⁺ and Fe³⁺) and hydroxide ions (OH⁻) leads to the formation of various iron oxides and hydroxides, collectively known as rust. This is not a simple, single-step reaction, but rather a complex process involving several intermediate steps and the influence of various environmental factors.

The Role of pH and Other Environmental Factors

The pH of the water plays a significant role in determining the type and rate of rust formation. In acidic conditions (low pH), the reaction is accelerated, while in alkaline conditions (high pH), the reaction is slowed. Other factors, such as the presence of dissolved salts, temperature, and exposure to UV radiation, also influence the rate and type of rust formation. These factors can create electrochemical cells, accelerating the corrosion process.

The Composition of Rust: A Mixture of Compounds

Rust is not a single chemical compound but rather a complex mixture of hydrated iron(III) oxides (Fe₂O₃·nH₂O) and iron(III) oxyhydroxides (FeO(OH), Fe(OH)₃). The exact composition varies depending on the environmental conditions.

-

Hydrated Iron(III) Oxides (Fe₂O₃·nH₂O): These are the primary components of rust, exhibiting various degrees of hydration (the number of water molecules, 'n', varies).

-

Iron(III) Oxyhydroxides (FeO(OH), Fe(OH)₃): These compounds contribute to the overall rust structure, influencing its properties and appearance.

Types of Corrosion: Beyond Simple Rust

While the iron-water reaction often manifests as rust, it's crucial to understand that corrosion can take different forms depending on the environment and the specific conditions:

Uniform Corrosion: Even Degradation

This is the most common type of corrosion, characterized by a relatively uniform degradation of the iron surface. Rust forms evenly across the exposed area.

Galvanic Corrosion: Contact with Different Metals

When iron is in contact with a less reactive metal (like copper or zinc), galvanic corrosion occurs. The iron acts as the anode, undergoing oxidation and corroding more rapidly than it would alone.

Pitting Corrosion: Localized Attack

This type of corrosion involves localized attack, resulting in the formation of pits or holes on the iron surface. This is often initiated by imperfections or impurities on the surface.

Crevice Corrosion: Restricted Oxygen Access

Corrosion concentrated in crevices or narrow gaps where oxygen access is restricted. The restricted oxygen creates a differential aeration cell, leading to rapid corrosion within the crevice.

Preventing Rust: Mitigation Strategies

Given the significant economic and structural implications of rust, various strategies are employed to mitigate its formation. These include:

Protective Coatings: Barriers Against Oxidation

Applying protective coatings, such as paints, varnishes, or zinc galvanization, creates a physical barrier that prevents water and oxygen from reaching the iron surface.

Cathodic Protection: Electrochemical Prevention

This method involves using a more reactive metal (like zinc or magnesium) as a sacrificial anode. The sacrificial anode corrodes preferentially, protecting the iron structure.

Alloying: Enhancing Corrosion Resistance

Adding other elements to iron, creating alloys such as stainless steel, significantly enhances corrosion resistance. These alloys contain chromium or nickel which form a passive oxide layer that protects the underlying iron.

Inhibitors: Chemical Retardants

Chemical inhibitors can be added to water or applied to the iron surface to slow down the oxidation process. These inhibitors interfere with the electrochemical reactions involved in rust formation.

The Broader Significance: Environmental and Economic Impacts

The reaction between iron and water is not just a chemical curiosity; it has profound environmental and economic impacts:

Environmental Impacts: Water Quality and Pollution

Rust formation can affect water quality through the release of iron ions and other contaminants into water bodies. This can have negative consequences for aquatic ecosystems.

Economic Impacts: Infrastructure Maintenance and Material Loss

Rusting causes billions of dollars in damage annually to infrastructure, vehicles, and other iron-containing materials, requiring significant costs for maintenance and replacement.

Conclusion: A Continuing Area of Research

The chemical reaction between iron and water, resulting in rust formation, is a complex and multifaceted process with significant implications. While we have developed effective methods for mitigating rust, ongoing research continues to explore new materials, coatings, and inhibitors to enhance corrosion protection and reduce the substantial economic and environmental costs associated with this ubiquitous process. Understanding the underlying chemistry is key to developing innovative solutions for this persistent challenge. The exploration into the intricacies of this reaction continues to drive advancements in materials science, engineering, and environmental protection. From improving the durability of bridges and pipelines to creating more sustainable materials, the study of iron's reaction with water remains a vital area of scientific inquiry.

Latest Posts

Latest Posts

-

What Are The Prime Factors Of 87

Mar 18, 2025

-

Are Diagonals Of A Parallelogram Perpendicular

Mar 18, 2025

-

How Do You Separate Salt And Sugar

Mar 18, 2025

-

On Fahrenheit Scale Water Boils At

Mar 18, 2025

-

Least Common Multiple Of 3 9 And 12

Mar 18, 2025

Related Post

Thank you for visiting our website which covers about Chemical Reaction Of Iron And Water . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.