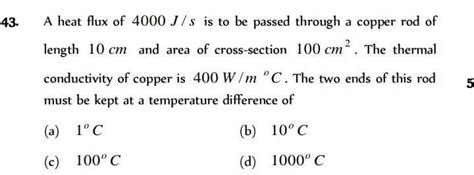

A Heat Flux Of 4000 J/s Is To Be Passed

Juapaving

Mar 06, 2025 · 6 min read

Table of Contents

A Heat Flux of 4000 J/s: Design Considerations and Practical Applications

A heat flux of 4000 J/s (4 kW) represents a significant thermal load, demanding careful consideration in design and application. This article delves into the practical implications of managing such a heat flux, exploring various scenarios, materials, and techniques for efficient heat transfer and dissipation. We will examine different methods for handling this thermal energy, considering factors like material selection, surface area, and cooling methods. Understanding these factors is crucial for designing robust and efficient systems capable of safely managing high heat fluxes.

Understanding Heat Flux and its Significance

Before diving into specific solutions, it's essential to understand what heat flux signifies. Heat flux, measured in Watts per square meter (W/m²) or Joules per second per square meter (J/s/m²), quantifies the rate of heat transfer per unit area. A heat flux of 4000 J/s, without specifying the area, lacks practical meaning. Therefore, we must consider the area over which this heat is distributed. A smaller area will require more intense cooling strategies compared to a larger area.

Example: A heat flux of 4000 J/s distributed over 1 square meter (1 m²) results in a heat flux density of 4000 W/m². However, the same 4000 J/s distributed over 0.1 square meters (0.1 m²) yields a much higher heat flux density of 40,000 W/m², presenting a considerably greater engineering challenge.

Factors Influencing Heat Transfer and Dissipation

Several critical factors influence how effectively a system can manage a 4000 J/s heat flux:

1. Surface Area: Maximizing Heat Transfer

Increasing the surface area over which the heat is dissipated is a fundamental approach to reducing the heat flux density. This allows for a lower temperature gradient and eases the cooling process. Techniques like using fins, extended surfaces, or microchannels significantly enhance surface area, promoting more efficient heat transfer.

Practical Applications: Heat sinks are prime examples; their extended surfaces maximize contact with the cooling medium (air or liquid), increasing the rate of heat dissipation. Microchannel heat exchangers are another advanced technique utilized in high-performance applications like electronics cooling.

2. Material Selection: Thermal Conductivity Matters

The thermal conductivity of the materials involved directly impacts heat transfer. Materials with high thermal conductivity efficiently transfer heat away from the heat source. Metals, particularly copper and aluminum, are excellent choices due to their high thermal conductivity. However, the cost and weight of these materials must be considered.

Material Considerations: Choosing the right material depends on several factors including cost, weight, corrosion resistance, and the operating environment. For extreme environments, materials with high temperature resistance may be necessary.

3. Cooling Methods: Conduction, Convection, and Radiation

Effective heat dissipation relies on efficient cooling methods. These include:

- Conduction: Direct transfer of heat through a material. This method relies heavily on the material's thermal conductivity.

- Convection: Heat transfer through the movement of fluids (liquids or gases). This is a highly effective method, especially with forced convection (using fans or pumps).

- Radiation: Heat transfer through electromagnetic waves. This method becomes increasingly important at high temperatures.

Optimal Cooling Strategies: A combination of these methods often provides the most efficient cooling. For instance, a heat sink (conduction) with forced air convection can effectively manage a significant heat flux. Liquid cooling systems, particularly those using high-performance fluids, offer superior cooling capabilities for extremely high heat fluxes.

4. Heat Transfer Fluids: Enhancing Convection

For convection-based cooling, the choice of heat transfer fluid significantly influences efficiency. Water is a common choice due to its high specific heat capacity, but other fluids like oils or specialized coolants may be more suitable for specific applications.

Fluid Properties: Factors such as viscosity, thermal conductivity, and boiling point influence the fluid's effectiveness. For high-temperature applications, fluids with high boiling points are essential to prevent boiling and subsequent cooling failure.

Specific Applications and Design Considerations

The management of a 4000 J/s heat flux varies greatly depending on the specific application. Let's consider a few examples:

1. Electronics Cooling: High-Density Circuit Boards

High-performance computing and electronic devices often generate significant heat. Effective cooling is crucial to prevent overheating and system failure. Strategies include:

- Heat sinks with forced air cooling: Simple and cost-effective for moderate heat fluxes.

- Liquid cooling systems: Provide superior cooling for high heat flux densities.

- Microchannel heat sinks: Enable efficient heat removal in confined spaces.

Thermal Management Solutions: The choice of cooling technique depends on factors like the size and density of the components, the available space, and the required operating temperature.

2. Industrial Processes: High-Temperature Reactions

Industrial processes like chemical reactions or metal processing often generate substantial heat. Managing this heat is vital for process control and safety.

- Heat exchangers: Efficiently transfer heat from the process to a cooling medium.

- Water-cooled jackets: Provide direct cooling to reaction vessels.

- Forced convection cooling systems: Utilize fans or blowers to remove heat.

Safety and Process Control: Ensuring safe and efficient heat removal is crucial in industrial applications. Appropriate safety measures and monitoring systems are necessary to prevent accidents.

3. Power Electronics: Inverters and Converters

Power electronics devices, such as inverters and converters, can generate considerable heat due to switching losses and resistive heating. Effective thermal management is paramount for reliability and efficiency.

- Heat sinks with fans: Essential for dissipating heat from power transistors and other components.

- Liquid cooling systems: Provide superior cooling for high-power devices.

- Thermal interface materials: Improve heat transfer between components and heat sinks.

Reliability and Efficiency: Proper thermal management enhances the efficiency and lifespan of power electronics equipment. The choice of cooling technique depends on the device's power rating and operating environment.

Advanced Techniques for High Heat Flux Management

For extremely high heat flux densities, advanced techniques may be necessary:

- Immersion cooling: Submerging components in a dielectric fluid for efficient heat removal.

- Two-phase cooling: Utilizing the latent heat of vaporization to enhance heat transfer.

- Thermoelectric cooling: Utilizing the Peltier effect for localized cooling.

These techniques are more complex and expensive but are essential for managing extremely high heat fluxes encountered in specialized applications.

Conclusion: A Holistic Approach to Heat Management

Managing a heat flux of 4000 J/s requires a holistic approach. Careful consideration of surface area, material selection, cooling methods, and the specific application is crucial for designing a reliable and efficient system. Understanding the limitations of different techniques and selecting the most appropriate strategy based on cost, performance, and safety requirements is paramount. Remember that optimization involves balancing various factors to achieve the best possible outcome. Furthermore, continuous monitoring and maintenance are crucial to ensure the long-term effectiveness of any heat management system. Advances in materials science and thermal engineering continue to provide innovative solutions for managing ever-increasing heat fluxes in diverse applications. Staying abreast of these advancements is key to designing cutting-edge systems that effectively manage thermal energy and meet evolving industry demands.

Latest Posts

Latest Posts

-

Dna Can Be Found In What Two Organelles

Mar 06, 2025

-

What Are The Basic Building Blocks Of Matter

Mar 06, 2025

-

How Many Corners Does A Square Have

Mar 06, 2025

-

Anything That Has Mass And Occupies Space

Mar 06, 2025

-

Lowest Common Multiple Of 5 And 15

Mar 06, 2025

Related Post

Thank you for visiting our website which covers about A Heat Flux Of 4000 J/s Is To Be Passed . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.