Which Of The Following Are Manufactured By Microbial Fermentation

Juapaving

Mar 23, 2025 · 7 min read

Table of Contents

Which of the Following Are Manufactured by Microbial Fermentation? A Deep Dive into Microbial Processes

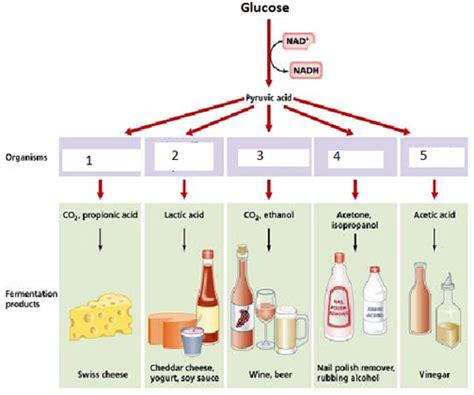

Microbial fermentation, a process harnessing the metabolic capabilities of microorganisms, plays a pivotal role in manufacturing a vast array of products. From everyday food items to sophisticated pharmaceuticals, the impact of microbial fermentation is undeniable. This comprehensive article delves into the diverse range of products manufactured through this powerful biotechnological process, exploring the underlying mechanisms and the significant contributions to various industries.

Understanding Microbial Fermentation

Before exploring specific products, it's crucial to grasp the fundamental principles of microbial fermentation. This process involves the anaerobic (without oxygen) or aerobic (with oxygen) breakdown of organic substances by microorganisms like bacteria, yeasts, and fungi. These microbes, through their metabolic pathways, convert substrates (raw materials) into desired products. The process can be broadly categorized into:

Types of Microbial Fermentation:

-

Aerobic Fermentation: This type requires oxygen for the microbial growth and product formation. Examples include the production of certain antibiotics and some organic acids.

-

Anaerobic Fermentation: This occurs in the absence of oxygen. Many familiar food products, such as yogurt and bread, are produced through anaerobic fermentation.

-

Submerged Fermentation: This involves cultivating microorganisms in a liquid medium, providing efficient mixing and oxygen transfer (in aerobic processes). It's widely used for producing antibiotics and other pharmaceuticals.

-

Solid-State Fermentation: This uses solid substrates, such as grains or agricultural residues, as a growth medium. It's commonly employed in the production of enzymes and some fermented foods.

Food and Beverages Produced via Microbial Fermentation

Microbial fermentation is the cornerstone of many traditional and modern food and beverage production methods. The process not only enhances the flavor, texture, and shelf life of these products but also contributes essential nutrients and beneficial microorganisms.

1. Dairy Products:

-

Yogurt: Created through the fermentation of milk by lactic acid bacteria (LAB), primarily Lactobacillus bulgaricus and Streptococcus thermophilus. These bacteria convert lactose (milk sugar) into lactic acid, resulting in the characteristic tangy flavor and thickened texture.

-

Cheese: A wide variety of cheeses are produced through the fermentation of milk by different combinations of bacteria, yeasts, and molds. The specific microorganisms and fermentation conditions determine the unique flavor, texture, and aroma of each cheese type.

-

Kefir: A fermented milk drink produced by a mixed culture of LAB and yeasts. The fermentation process yields a slightly sour, effervescent beverage with a distinctive texture.

-

Buttermilk: Though traditionally made as a byproduct of butter production, modern buttermilk is produced through the fermentation of milk with LAB, similar to yogurt.

2. Bread and Bakery Products:

-

Bread: Yeast fermentation is essential for bread making. Yeast cells consume sugars in the dough, producing carbon dioxide gas, which causes the dough to rise. This fermentation process also contributes to the characteristic flavor and aroma of bread.

-

Sourdough Bread: This type of bread utilizes a sourdough starter, a mixture of flour and water that has been fermented by wild yeasts and LAB. The starter provides unique flavors and textures to the bread.

3. Alcoholic Beverages:

-

Beer: The fermentation of barley malt by yeast (typically Saccharomyces cerevisiae) produces ethanol and carbon dioxide, which are the primary components of beer. Different yeast strains and fermentation conditions result in diverse beer styles.

-

Wine: Grape juice is fermented by yeast, usually Saccharomyces cerevisiae, to produce wine. The type of grapes, yeast strains, and fermentation techniques all influence the wine's characteristics.

-

Sake: Rice is fermented by yeast to produce this Japanese alcoholic beverage. The specific fermentation methods and rice varieties contribute to the unique flavor profiles of various sake types.

4. Other Fermented Foods:

-

Soy Sauce: Soybeans and wheat are fermented using a mixed culture of microorganisms, primarily Aspergillus oryzae and various bacteria, to produce soy sauce. This fermentation process yields a complex umami flavor.

-

Miso: A fermented paste made from soybeans, rice, and salt, inoculated with Aspergillus oryzae. The fermentation results in a savory condiment with varied flavor profiles depending on the ingredients and fermentation time.

-

Kimchi: This spicy Korean side dish involves fermenting vegetables, typically Napa cabbage and radishes, with various spices and LAB. The fermentation process results in a tangy and spicy flavor, along with probiotic benefits.

-

Sauerkraut: Cabbage is fermented by LAB, primarily Leuconostoc mesenteroides, to produce sauerkraut. The fermentation process gives sauerkraut its characteristic sour taste and crunchy texture.

Pharmaceuticals and Biochemicals Produced by Microbial Fermentation

Beyond food and beverages, microbial fermentation is a cornerstone of pharmaceutical and biochemical production. This area has seen remarkable advancements, leading to the development of various life-saving drugs and valuable biomolecules.

1. Antibiotics:

Numerous antibiotics, including penicillin, streptomycin, tetracycline, and erythromycin, are produced by microbial fermentation. Different microorganisms, such as Penicillium species for penicillin and Streptomyces species for streptomycin, are cultivated in large-scale fermenters to produce these vital medicines.

2. Vitamins:

Many vitamins, including vitamin B12, riboflavin (vitamin B2), and vitamin C (ascorbic acid), are produced through microbial fermentation. Specifically engineered microorganisms are used to efficiently synthesize these essential nutrients.

3. Enzymes:

Industrial enzymes, like amylases, proteases, and lipases, are widely produced by microbial fermentation. These enzymes are used in various industries, including food processing, textile manufacturing, and biofuel production.

4. Organic Acids:

Citric acid, lactic acid, acetic acid, and other organic acids are produced on a large scale through microbial fermentation. These acids are used in food and beverage industries, pharmaceuticals, and various other applications.

5. Amino Acids:

Several amino acids, essential building blocks of proteins, are manufactured by microbial fermentation. These amino acids are used as dietary supplements, food additives, and in the production of pharmaceuticals.

Industrial Applications of Microbial Fermentation

The versatility of microbial fermentation extends beyond food and pharmaceuticals. It's utilized in several industrial processes:

-

Biofuel Production: Microbial fermentation is employed in the production of biofuels like ethanol and butanol from renewable resources like biomass. This sustainable approach offers an alternative to fossil fuels.

-

Bioremediation: Microorganisms are used to clean up environmental pollutants through bioremediation processes. These processes leverage the metabolic capabilities of microbes to break down harmful substances.

-

Wastewater Treatment: Microbial fermentation plays a crucial role in wastewater treatment plants. Microorganisms degrade organic matter in wastewater, contributing to cleaner water discharge.

-

Bioplastics Production: Microbial fermentation is used in the production of biodegradable plastics, offering a sustainable alternative to traditional plastics derived from petroleum.

Advantages of Using Microbial Fermentation

The widespread adoption of microbial fermentation stems from several key advantages:

-

Sustainability: Microbial fermentation utilizes renewable resources, contributing to more sustainable manufacturing processes.

-

Cost-Effectiveness: Microbial fermentation can be a cost-effective method for producing various products, especially compared to chemical synthesis.

-

Scalability: Fermentation processes can be scaled up to meet large-scale industrial demands.

-

Specificity: Microbial fermentation allows for the production of highly specific products with minimal waste.

-

Safety: Compared to chemical synthesis, microbial fermentation often involves less hazardous materials and processes.

Future Trends in Microbial Fermentation

The field of microbial fermentation is constantly evolving. Future trends include:

-

Metabolic Engineering: Genetic engineering techniques are employed to enhance the metabolic capabilities of microorganisms for producing desired products more efficiently.

-

Systems Biology: Advanced computational tools and systems biology approaches are used to optimize fermentation processes and improve product yields.

-

Synthetic Biology: The design and construction of new biological systems for specific applications is a promising area.

-

Automation and Process Control: Automation and advanced process control techniques are improving efficiency and consistency in fermentation processes.

-

Sustainable Fermentation Technologies: Research is focusing on developing more sustainable fermentation processes, such as using less energy and reducing waste.

Conclusion

Microbial fermentation is a powerful biotechnology that plays a critical role in manufacturing a wide spectrum of products, ranging from everyday food and beverages to sophisticated pharmaceuticals and industrial chemicals. Its versatility, sustainability, and cost-effectiveness ensure its continued importance in various industries. As research continues to advance, the applications of microbial fermentation are likely to expand even further, contributing to a more sustainable and efficient future. The examples provided throughout this article merely scratch the surface of the incredible potential this process holds for addressing global challenges and improving our lives.

Latest Posts

Latest Posts

-

Is Water A Mixture Or A Compound

Mar 25, 2025

-

Is 4 A Multiple Of 2

Mar 25, 2025

-

What Is The Square Root Of 160

Mar 25, 2025

-

Least Common Multiple Of 3 9

Mar 25, 2025

-

Which Of The Following Is A Renewable Resource

Mar 25, 2025

Related Post

Thank you for visiting our website which covers about Which Of The Following Are Manufactured By Microbial Fermentation . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.