Most Abundant Metal In Earth's Crust

Juapaving

Mar 20, 2025 · 7 min read

Table of Contents

The Most Abundant Metal in Earth's Crust: Unveiling the Reign of Aluminum

Earth's crust, the outermost solid shell of our planet, is a treasure trove of diverse elements, forming the foundation of our continents and oceans. Among this vast array of minerals and metals, one reigns supreme in terms of abundance: aluminum. This article delves deep into the fascinating world of aluminum, exploring its geological prominence, its unique properties, its extraction processes, and its pervasive presence in modern society.

Aluminum: A Dominant Force in the Earth's Composition

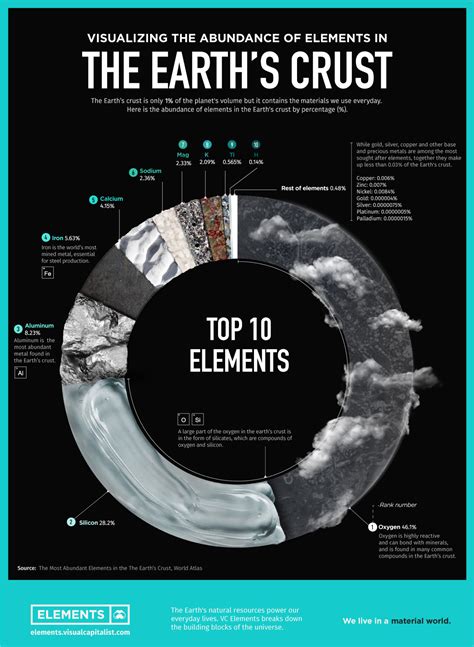

Aluminum isn't just abundant; it's overwhelmingly so. Constituting approximately 8.2% of the Earth's crust by weight, it significantly surpasses all other metals in terms of prevalence. Iron, often cited as the most abundant element overall, holds a higher percentage in the Earth as a whole (including the core), but when focusing solely on the crust, aluminum takes the crown. This dominance is largely due to its presence in numerous common silicate minerals, which form the bedrock of much of the Earth's landmass.

Understanding the Geological Distribution of Aluminum

Aluminum doesn't exist in its pure metallic form naturally. Instead, it's found in various aluminum silicate minerals, such as:

-

Feldspars: These are the most abundant group of minerals in the Earth's crust, comprising a significant portion of igneous, metamorphic, and sedimentary rocks. Orthoclase and plagioclase feldspars are prime examples, containing substantial amounts of aluminum.

-

Micas: Minerals like muscovite and biotite also contain significant aluminum within their crystal structures. These platy minerals are common constituents of many rock types.

-

Clay Minerals: Formed through the weathering and alteration of other silicate minerals, clay minerals like kaolinite and montmorillonite are rich in aluminum and are crucial components of soils.

-

Bauxite: While not as widespread as the silicates, bauxite is the primary ore used for aluminum extraction. This sedimentary rock is rich in hydrated aluminum oxides, including gibbsite, boehmite, and diaspore. Its formation is a complex geological process involving intense weathering and leaching of aluminum-rich parent rocks under specific environmental conditions.

The geographical distribution of bauxite deposits is uneven, concentrated in tropical and subtropical regions with a history of intense chemical weathering. Countries like Australia, Guinea, Brazil, and India are major producers of bauxite, reflecting the localized concentration of favorable geological conditions.

The Unique Properties of Aluminum: A Versatile Metal

Aluminum's abundance is matched by its remarkable versatility. Its unique properties make it an indispensable material across numerous industries:

-

Lightweight: Aluminum boasts an exceptionally low density, approximately one-third that of steel. This makes it ideal for applications where weight reduction is crucial, such as aerospace, automotive, and transportation industries.

-

High Strength-to-Weight Ratio: Despite its lightness, aluminum possesses surprisingly high tensile strength, making it robust and capable of withstanding significant stress. This characteristic is further enhanced through various alloying processes.

-

Corrosion Resistance: Aluminum forms a protective oxide layer on its surface, providing excellent resistance to corrosion and oxidation. This natural passivation layer safeguards it from degradation, making it suitable for outdoor applications and various corrosive environments.

-

Ductility and Malleability: Aluminum is highly ductile, meaning it can be drawn into wires, and malleable, meaning it can be hammered or rolled into sheets. This allows for easy shaping and fabrication, making it adaptable to a wide range of manufacturing processes.

-

Excellent Conductivity: Aluminum is a good conductor of both electricity and heat, making it valuable in electrical wiring, power transmission lines, and heat exchangers.

-

Recyclability: Aluminum is infinitely recyclable without any loss of its properties. This is environmentally advantageous, reducing the need for new bauxite mining and significantly lowering energy consumption in the production process.

Aluminum Extraction: From Bauxite to Metal

Transforming bauxite ore into pure aluminum is a complex and energy-intensive process. The primary method involves the Bayer process and the Hall-Héroult process.

The Bayer Process: Purifying the Aluminum

The Bayer process focuses on purifying the aluminum-containing components within bauxite. The process generally involves these steps:

-

Digestion: Bauxite ore is finely ground and then digested in a pressurized solution of sodium hydroxide (NaOH) at high temperatures. This dissolves the aluminum oxides (gibbsite, boehmite, and diaspore), leaving behind impurities like iron oxides and silica.

-

Separation: The resulting solution, containing dissolved aluminate, is separated from the insoluble residue (red mud) through filtration.

-

Precipitation: Aluminum hydroxide (Al(OH)3) is precipitated from the aluminate solution by carefully controlling the temperature and pH. This precipitation is crucial in separating aluminum from other dissolved impurities.

-

Calcination: The precipitated aluminum hydroxide is then heated to high temperatures (around 1000°C) in a process called calcination. This converts the aluminum hydroxide into alumina (Al2O3), a white powder.

The Hall-Héroult Process: Electrolytic Reduction

The Hall-Héroult process is the cornerstone of aluminum production, employing electrolysis to reduce alumina to pure aluminum metal. This crucial step involves:

-

Dissolution: Alumina is dissolved in molten cryolite (Na3AlF6), a natural mineral with a lower melting point than alumina. This creates an electrolyte bath that facilitates the electrolytic process.

-

Electrolysis: A direct current is passed through the molten electrolyte bath, causing the alumina to decompose into molten aluminum at the cathode (negative electrode) and oxygen gas at the anode (positive electrode).

-

Collection: The molten aluminum accumulates at the bottom of the electrolytic cell, where it can be periodically tapped and collected.

The Hall-Héroult process is exceptionally energy-intensive, requiring substantial amounts of electricity. This is a significant factor in the overall cost of aluminum production and underscores the importance of sustainable energy sources in the industry.

The Ubiquitous Presence of Aluminum in Modern Life

Aluminum's unique combination of properties and its abundance has led to its widespread use across a vast array of applications in modern society:

Transportation:

-

Automotive: Aluminum alloys are increasingly used in vehicles to reduce weight and improve fuel efficiency. This includes engine components, body panels, and wheels.

-

Aerospace: Aluminum's lightweight nature and high strength are indispensable in the aerospace industry, where weight savings translate directly to fuel efficiency and payload capacity. Airframes, engines, and various other components are often constructed from aluminum alloys.

-

Rail Transportation: Aluminum is also finding increasing application in high-speed rail vehicles, reducing overall weight and improving performance.

Packaging:

-

Aluminum Cans: The ubiquitous aluminum can is a testament to the metal's recyclability and corrosion resistance. Billions of aluminum cans are produced annually, demonstrating its dominance in the beverage packaging industry.

-

Foil: Aluminum foil is widely used for food packaging, providing a barrier against moisture, oxygen, and light.

Construction:

-

Building Materials: Aluminum is used in various construction applications, including window frames, doors, roofing, and cladding. Its durability, weather resistance, and lightweight nature make it an attractive option.

-

Structural Components: Aluminum alloys are employed in certain structural applications where lightweight high-strength materials are required.

Electrical Applications:

-

Wiring: Aluminum's high conductivity makes it a common choice for electrical wiring, especially in power transmission lines where large amounts of current need to be carried.

-

Electronic Components: Aluminum is used in various electronic components due to its conductivity and thermal properties.

Other Applications:

-

Consumer Goods: From cookware and kitchen utensils to sporting goods and furniture, aluminum finds its way into a vast array of consumer products.

-

Medical Devices: Aluminum's biocompatibility and corrosion resistance make it suitable for certain medical devices and implants.

Environmental Considerations: Balancing Benefits and Impacts

While aluminum's properties and applications are undeniably beneficial, its production and use also pose certain environmental challenges. The energy-intensive nature of aluminum production, particularly the Hall-Héroult process, contributes to greenhouse gas emissions. Furthermore, bauxite mining can lead to habitat destruction, water pollution (red mud disposal), and land degradation. However, advancements in sustainable mining practices, energy-efficient production technologies, and increased recycling rates are mitigating these impacts.

The Importance of Recycling: Closing the Loop

Recycling aluminum is crucial in reducing the environmental footprint of aluminum production. The energy required to recycle aluminum is significantly less than that needed to produce it from bauxite ore. Furthermore, recycling aluminum helps to conserve natural resources and reduce waste.

Conclusion: The Enduring Reign of Aluminum

Aluminum's dominance as the most abundant metal in the Earth's crust is a testament to its unique geological history and remarkable properties. Its versatility has led to its widespread use in a vast array of industries and applications, shaping our modern world. While environmental considerations remain important, the ongoing development of sustainable practices and the inherent recyclability of aluminum position this remarkable metal for continued prominence in the years to come. The story of aluminum is not just a geological narrative; it's a reflection of human ingenuity and our ability to harness the resources of our planet to create and innovate.

Latest Posts

Latest Posts

-

What Is The Difference Between Antiseptic And Antibiotic

May 09, 2025

-

How Fast Is 90 Km An Hour

May 09, 2025

-

The Time Of Maximum Daily Temperature Occurs

May 09, 2025

-

Matter Includes All Of The Following Except

May 09, 2025

-

What Is Found In Both Eukaryotic And Prokaryotic Cells

May 09, 2025

Related Post

Thank you for visiting our website which covers about Most Abundant Metal In Earth's Crust . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.