Is Rusting Iron A Chemical Change

Juapaving

Mar 05, 2025 · 6 min read

Table of Contents

Is Rusting Iron a Chemical Change? A Deep Dive into Oxidation and its Implications

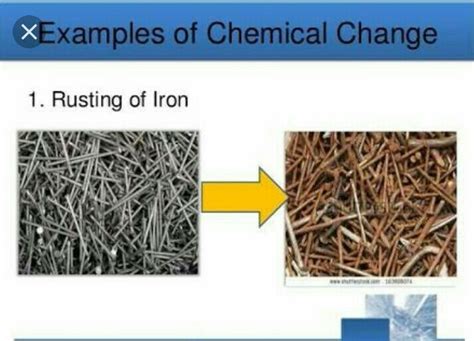

Rusting iron is a quintessential example of a chemical change, a process that fundamentally alters the composition and properties of a substance. Understanding this process requires delving into the intricacies of oxidation, chemical reactions, and the differences between chemical and physical changes. This comprehensive guide will explore the science behind rusting, its implications, and why it serves as a prime illustration of a chemical transformation.

What is Rusting?

Rust is the common name for iron oxide, specifically hydrated iron(III) oxide (Fe₂O₃·nH₂O). It's the result of a chemical reaction between iron (Fe) and oxygen (O₂) in the presence of water (H₂O). This reaction is a form of oxidation, where iron loses electrons and oxygen gains electrons. The resulting iron oxide is a reddish-brown, flaky substance that weakens and ultimately degrades the iron object.

The Chemical Reaction

The chemical equation for the rusting of iron is complex and not a single, straightforward reaction. It involves several steps and intermediate compounds. A simplified representation is:

4Fe(s) + 3O₂(g) + 6H₂O(l) → 4Fe(OH)₃(s)

This then further dehydrates to form the familiar rust:

2Fe(OH)₃(s) → Fe₂O₃·nH₂O(s) + 3H₂O(l)

This shows iron reacting with oxygen and water to form iron(III) hydroxide, which eventually dehydrates to form hydrated iron(III) oxide – rust. The 'n' in the formula indicates that the amount of water incorporated into the rust varies depending on conditions.

Why Rusting is a Chemical Change

Several key characteristics of rusting clearly demonstrate that it's a chemical change, not a physical one. Let's explore these distinctions:

1. Change in Composition: The Defining Factor

A fundamental difference between chemical and physical changes lies in the composition of the substance. Physical changes alter the form or appearance of a substance but not its chemical makeup. For example, melting ice is a physical change because it's still H₂O, just in a different state. However, rusting fundamentally alters the composition. Iron (Fe), oxygen (O₂), and water (H₂O) react to create a completely new substance: hydrated iron(III) oxide (Fe₂O₃·nH₂O). This new substance has entirely different properties from the original iron.

2. Irreversibility: You Can't Easily Get Back the Original Iron

Physical changes are often reversible. For example, you can freeze water and then melt it back into liquid water. Chemical changes, however, are usually irreversible without significant intervention. You cannot simply reverse the rusting process to regain the original iron. While some advanced techniques exist to remove rust, they often require significant effort and chemical processes. The original iron's structure and properties are lost. This irreversibility is a hallmark of chemical change.

3. Energy Changes: The Heat is On (or Off)

Chemical reactions often involve a change in energy, either releasing heat (exothermic) or absorbing heat (endothermic). Rusting is a slightly exothermic reaction, meaning it releases a small amount of heat. While not readily noticeable in everyday situations, the heat generated is evidence of the chemical bonds breaking and reforming during the reaction, another characteristic feature of chemical change. Physical changes, on the other hand, typically involve little or no heat exchange.

4. New Properties Emerge: Rust is Different

A chemical change produces a substance with entirely new properties compared to the original substances. Rust, for instance, is reddish-brown, flaky, and brittle. It's significantly less strong and durable than the original iron. These properties are entirely different from the metallic properties of iron. This change in properties is a strong indicator of a chemical transformation.

Factors Affecting Rusting Rate: A Closer Look

Several factors influence how quickly iron rusts. Understanding these factors is crucial for preventing or slowing down the process:

1. Exposure to Oxygen: The Oxidizer

Oxygen is essential for rusting. The more oxygen available, the faster the reaction proceeds. This explains why iron rusts faster in environments with high oxygen concentrations.

2. Exposure to Water: The Catalyst

Water acts as an electrolyte, facilitating the electron transfer between iron and oxygen. The presence of water accelerates the rusting process significantly. Completely dry iron will rust much more slowly, if at all.

3. Presence of Electrolytes: Speeding things up

Electrolytes are substances that conduct electricity when dissolved in water. The presence of electrolytes, such as salts, acids, or bases, further speeds up the rusting process. This is why saltwater environments are particularly corrosive to iron.

4. Temperature: A Warming Trend for Rust

Higher temperatures generally increase the rate of chemical reactions, including rusting. The higher the temperature, the faster the reaction between iron, oxygen, and water.

5. Surface Area: More Surface, More Rust

A larger surface area of iron exposed to oxygen and water leads to a faster rusting rate. This is why finely divided iron powder rusts much faster than a solid iron bar of the same mass.

Preventing Rust: Strategies and Techniques

Protecting iron from rust is crucial for preserving its structural integrity and preventing damage. Several methods are employed to prevent or slow down rusting:

1. Protective Coatings: A Barrier Against the Elements

Applying coatings like paint, oil, grease, or other protective materials creates a barrier between the iron and the environment, preventing contact with oxygen and water.

2. Galvanization: A Zinc Shield

Galvanization involves coating iron with zinc. Zinc is more reactive than iron, meaning it oxidizes first, protecting the underlying iron from rust.

3. Cathodic Protection: Electronic Shielding

Cathodic protection uses an external electrical current to protect the iron from rusting. This method is often used for large structures like pipelines and ships.

4. Alloying: Mixing it Up

Alloying involves mixing iron with other metals to improve its resistance to rust. Stainless steel, for instance, is an alloy of iron, chromium, and nickel, known for its excellent corrosion resistance.

Conclusion: Rusting – A Chemical Transformation

Rusting is undeniably a chemical change. The formation of hydrated iron(III) oxide from iron, oxygen, and water results in a new substance with altered properties. The irreversibility of the process, the energy changes involved, and the emergence of new characteristics all point towards a fundamental chemical transformation. Understanding the chemistry behind rusting allows us to develop effective strategies for preventing this common and often destructive process. From understanding the reaction's mechanism to implementing practical preventative measures, the study of rusting provides a clear and compelling example of the power and importance of chemical reactions in our everyday lives. The implications extend beyond simple observations to practical applications in material science, engineering, and conservation efforts. Continued research into the complexities of iron oxidation will continue to refine our ability to protect iron structures and prevent the significant economic and environmental consequences associated with rust formation.

Latest Posts

Latest Posts

-

What Is The Gcf Of 42 And 28

Mar 06, 2025

-

The Division Of The Nucleus Is Called

Mar 06, 2025

-

Highest Common Factor Of 8 And 16

Mar 06, 2025

-

What Are The Factors For 11

Mar 06, 2025

-

Least Common Multiple Of 12 And 8

Mar 06, 2025

Related Post

Thank you for visiting our website which covers about Is Rusting Iron A Chemical Change . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.