How Can We Reduce The Friction

Juapaving

Mar 13, 2025 · 6 min read

Table of Contents

How Can We Reduce Friction? Exploring Solutions in Various Contexts

Friction. It's a force we encounter daily, from the simple act of walking to the complex workings of a machine. While sometimes beneficial (think car brakes!), often friction is the enemy, hindering efficiency, wasting energy, and causing wear and tear. This article delves into the multifaceted nature of friction, exploring its various forms and offering practical solutions for its reduction across diverse fields.

Understanding the Nature of Friction

Before we delve into solutions, let's establish a clear understanding of friction itself. At its core, friction is a force that opposes motion between two surfaces in contact. This opposition arises from the microscopic irregularities on these surfaces, which interlock and resist sliding past each other. Several factors influence the magnitude of frictional force:

Key Factors Affecting Friction

- Nature of the surfaces: Rougher surfaces exhibit higher friction than smoother ones. Think sandpaper versus glass.

- Normal force: The force pressing the surfaces together. The harder you push, the greater the friction.

- Material properties: Different materials possess varying coefficients of friction. Steel on steel has higher friction than Teflon on steel.

Reducing Friction: A Multi-pronged Approach

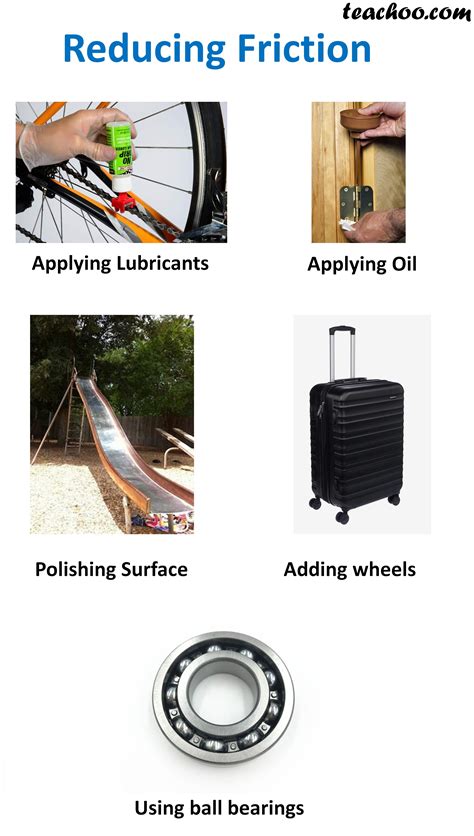

The strategies for friction reduction are diverse and depend heavily on the specific context. We'll explore several key approaches:

1. Lubrication: The Classic Solution

Lubrication is arguably the oldest and most widely used method for reducing friction. Lubricants, such as oils and greases, create a thin film between surfaces, separating them and minimizing direct contact. This dramatically reduces the interlocking of surface irregularities.

Types of Lubricants and Their Applications

- Liquid lubricants: Oils are ideal for moving parts, providing a low-viscosity film that allows for smooth movement. Engine oil, for instance, is crucial for the smooth operation of a car engine.

- Grease lubricants: Greases are thicker than oils and provide better adhesion and protection against wear, making them suitable for applications where lubrication needs to withstand pressure or maintain its position over time. Wheel bearings often use grease.

- Solid lubricants: Materials like graphite and molybdenum disulfide are used in high-temperature or high-pressure environments where liquid lubricants would fail. These solid lubricants form a protective layer, reducing friction and wear.

Choosing the Right Lubricant

Selecting the appropriate lubricant requires careful consideration of several factors, including temperature, pressure, speed, and the materials involved. The wrong lubricant can lead to increased friction, wear, and even equipment failure.

2. Surface Modification: Smoothing the Way

Reducing the roughness of contacting surfaces directly impacts friction. This can be achieved through various methods:

Surface Treatments

- Polishing: A mechanical process that removes surface irregularities, creating a smoother, more polished surface. This method is effective for reducing friction in many applications, from precision engineering to jewelry making.

- Honing: A precision machining process that improves surface finish and removes imperfections, resulting in a more accurate and smoother surface. Honing is commonly used in engine cylinders to reduce friction and improve efficiency.

- Electroplating: Applying a thin layer of a different metal can improve surface smoothness and reduce friction. This is particularly useful when dealing with corrosion-prone materials.

- Coatings: Applying specialized coatings like Teflon or DLC (diamond-like carbon) can significantly reduce friction and improve wear resistance. These coatings are used in a wide range of applications, from cookware to aerospace components.

3. Material Selection: Choosing the Right Partners

The materials used in contacting surfaces significantly influence friction. Selecting materials with low coefficients of friction can dramatically reduce frictional forces.

Low-Friction Materials

- Plastics: Many plastics, such as Teflon and nylon, possess exceptionally low coefficients of friction, making them ideal for applications where minimal friction is crucial.

- Ceramics: Certain ceramics exhibit low friction and high wear resistance, making them suitable for demanding applications like engine components.

- Composite materials: Combining different materials can create composites with tailored frictional properties. These materials are increasingly used in aerospace and automotive industries.

4. Improved Design and Engineering: Thinking Outside the Box

Innovative design and engineering play a vital role in reducing friction. This involves reconsidering the way systems are built and operated.

Design Strategies

- Bearing design: Employing appropriate bearing types (ball bearings, roller bearings, etc.) significantly reduces friction in rotating systems. The choice of bearing type depends on factors like load, speed, and cost.

- Aerodynamic design: Reducing air resistance through streamlined designs minimizes friction in high-speed applications like automobiles and airplanes. This is crucial for fuel efficiency and speed.

- Hydrodynamic lubrication: Using fluid pressure to separate surfaces is an effective way to reduce friction, especially in high-speed applications. This principle is used in many hydrodynamic bearings.

- Magnetic levitation (Maglev): Eliminating physical contact altogether by using magnetic fields to levitate objects is a cutting-edge technology that virtually eliminates friction. This technology is finding applications in high-speed trains and other specialized applications.

5. Minimizing Contact Area: Less is More

Reducing the area of contact between surfaces can reduce friction. This can be achieved through various methods:

Contact Area Reduction

- Point contact: Reducing the contact to a point, like a needle on a record player (though outdated!), minimizes friction but increases stress concentration, requiring careful material selection.

- Line contact: Using a line contact, such as a roller, reduces friction compared to surface contact, improving efficiency.

- Optimized geometries: Designing components with strategically reduced contact areas can significantly minimize friction.

Reducing Friction in Specific Applications

The methods for reducing friction are not one-size-fits-all. Let's explore some specific examples:

Reducing Friction in Engines

Internal combustion engines rely heavily on lubrication and material selection to minimize friction. High-quality engine oil, precisely engineered bearings, and the use of low-friction materials (like aluminum alloys) are all crucial for maximizing engine efficiency and lifespan.

Reducing Friction in Manufacturing Processes

Friction in manufacturing can lead to increased energy consumption and wear on machinery. Techniques such as improved lubrication, specialized coatings, and the use of low-friction materials significantly reduce these issues, leading to improved productivity and reduced costs.

Reducing Friction in Transportation

Reducing friction in transportation, whether in automobiles, trains, or airplanes, is crucial for fuel efficiency and speed. Aerodynamic design, high-quality bearings, and low-friction tires all contribute to improved performance.

Reducing Friction in Medical Devices

In medical devices, minimizing friction is critical for smooth operation and to avoid tissue damage. Materials with low coefficients of friction and specialized surface treatments are essential for these applications.

Conclusion: A Continuous Pursuit

Reducing friction is a continuous pursuit across various fields. As technology advances, so do the methods for minimizing this often-overlooked force. From the microscopic level of surface treatments to the macroscopic scale of aerodynamic design, the strategies discussed here highlight the multifaceted nature of friction reduction. By understanding the fundamental principles and employing appropriate techniques, we can significantly enhance efficiency, reduce wear, save energy, and create a smoother, more efficient world. The ongoing research and development in materials science, engineering, and lubrication technology promise even more innovative solutions in the future.

Latest Posts

Latest Posts

-

Is 19 A Prime Number Or A Composite Number

May 09, 2025

-

Is Force Increase On An Inclined Plane

May 09, 2025

-

Interesting Words That Start With V

May 09, 2025

-

Compare And Contrast A Light Microscope And An Electron Microscope

May 09, 2025

-

What Is 6 25 Meters In Feet And Inches

May 09, 2025

Related Post

Thank you for visiting our website which covers about How Can We Reduce The Friction . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.