Difference Between Composite Materials And Alloys

Juapaving

Mar 28, 2025 · 7 min read

Table of Contents

Delving Deep: Composite Materials vs. Alloys – A Comprehensive Comparison

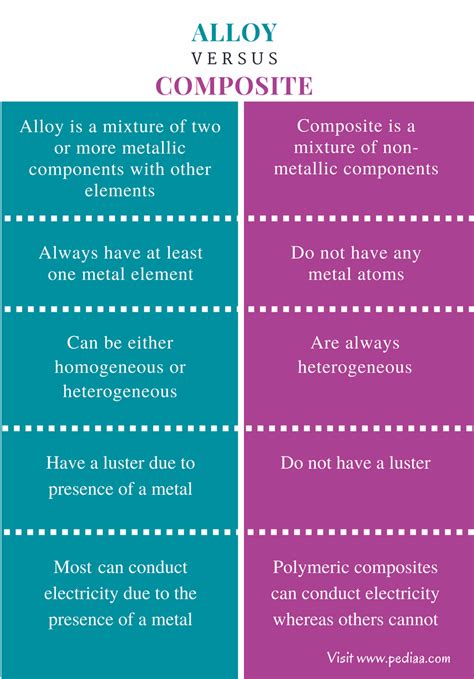

The world of materials science is vast and intricate, encompassing a diverse range of substances with unique properties and applications. Two prominent classes of materials frequently used in advanced engineering and manufacturing are composite materials and alloys. While both offer enhanced properties compared to their constituent components, they differ significantly in their structure, fabrication methods, and resulting characteristics. Understanding these differences is crucial for engineers and designers selecting materials for specific applications. This article provides a comprehensive comparison of composite materials and alloys, highlighting their key distinctions and exploring their respective advantages and disadvantages.

What are Composite Materials?

Composite materials are engineered materials composed of two or more distinct constituent materials with significantly different physical and chemical properties. These materials are combined to achieve a synergistic effect, resulting in a material with superior properties compared to its individual components. The combination isn't merely a mixture; it's a carefully designed structure where each component plays a specific role.

Key Characteristics of Composites:

- Matrix Phase: This is the continuous phase that binds the reinforcing phase together and distributes loads. It can be a polymer (thermoset or thermoplastic), metal, or ceramic.

- Reinforcement Phase: This phase provides strength and stiffness to the composite. It is typically in the form of fibers (glass, carbon, aramid), particles (silica, alumina), or whiskers (short, high-aspect-ratio fibers).

- Synergistic Properties: The key advantage of composites is the ability to combine the best properties of each constituent. For example, a polymer matrix can provide flexibility and toughness, while carbon fibers offer high strength and stiffness.

Types of Composite Materials:

The classification of composites is primarily based on the matrix material:

-

Polymer Matrix Composites (PMCs): These are the most common type, utilizing polymers as the matrix and fibers as the reinforcement. Examples include fiberglass-reinforced polymers (FRP), carbon fiber-reinforced polymers (CFRP), and aramid fiber-reinforced polymers (AFRP). They are lightweight, strong, and relatively inexpensive, making them suitable for various applications, from automotive parts to aerospace components.

-

Metal Matrix Composites (MMCs): These composites use metals as the matrix and reinforcement materials can include ceramics (e.g., silicon carbide, alumina), or other metals. MMCs exhibit high strength, stiffness, and high-temperature capabilities. They are used in applications requiring high-performance at elevated temperatures, such as aerospace engines and high-speed cutting tools.

-

Ceramic Matrix Composites (CMCs): These materials use ceramics as the matrix, often reinforced with ceramic fibers or whiskers. CMCs possess excellent high-temperature strength, corrosion resistance, and wear resistance. They are employed in demanding applications like heat shields, gas turbine components, and advanced engine parts.

What are Alloys?

Alloys are metallic materials formed by combining two or more metallic elements, or a metallic element and a non-metallic element, resulting in a homogenous mixture. The resulting material is typically a solid solution, intermetallic compound, or a mixture of both. The process of creating an alloy involves melting and mixing the constituent elements, followed by solidification.

Key Characteristics of Alloys:

-

Solid Solution: The alloying elements dissolve in the base metal, forming a solid solution that alters the base metal’s properties. This can result in improved strength, hardness, corrosion resistance, or other desirable characteristics.

-

Intermetallic Compounds: These are distinct chemical compounds formed between the alloying elements. They often have specific crystal structures and unique properties that can significantly influence the alloy's overall performance.

-

Microstructure: The microstructure of an alloy (the arrangement of grains and phases) profoundly impacts its properties. Heat treatments can modify the microstructure, thereby tailoring the alloy's properties for specific applications.

Types of Alloys:

Alloys are classified based on their primary constituent element:

-

Iron Alloys (Steels and Cast Irons): These are the most widely used alloys, comprising iron as the base metal. Steels are typically alloyed with carbon and other elements (chromium, nickel, manganese) to enhance strength, toughness, and hardenability. Cast irons contain higher carbon content and are known for their castability and machinability.

-

Aluminum Alloys: Aluminum alloys are known for their lightweight, corrosion resistance, and good strength-to-weight ratio. They are extensively used in aerospace, automotive, and packaging industries. Common alloying elements include copper, magnesium, and silicon.

-

Copper Alloys (Brasses and Bronzes): Copper alloys are valued for their electrical conductivity, corrosion resistance, and ductility. Brasses are copper-zinc alloys, while bronzes are copper alloys containing other elements like tin, aluminum, or silicon.

-

Titanium Alloys: Titanium alloys are characterized by their high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. They are used in aerospace, medical implants, and chemical processing industries.

A Detailed Comparison: Composites vs. Alloys

| Feature | Composite Materials | Alloys |

|---|---|---|

| Composition | Two or more distinct materials (matrix and reinforcement) | Two or more metallic elements (or a metal and a non-metal) |

| Structure | Heterogeneous; distinct phases are visible | Homogeneous; a uniform mixture at the macroscopic level |

| Bonding | Primarily mechanical (fiber-matrix interface) or chemical | Primarily metallic bonding |

| Properties | Tailorable; synergistic combination of constituent properties | Properties modified by alloying elements |

| Fabrication | Layering, molding, pultrusion, filament winding | Melting, casting, forging, rolling |

| Strength | High strength-to-weight ratio (especially with fiber reinforcement) | High strength, depending on alloy composition and treatment |

| Stiffness | High stiffness, especially with high-modulus reinforcement | High stiffness, depending on alloy composition and treatment |

| Ductility | Can vary widely depending on matrix and reinforcement | Generally ductile, though this can be reduced by alloying |

| Fracture Toughness | Can be high, particularly with ductile matrices | Can be high or low, depending on the alloy |

| Fatigue Resistance | Varies greatly depending on the constituent materials | Varies greatly depending on the alloy composition and treatment |

| Cost | Can range from relatively low to very high | Can range from relatively low to very high |

| Applications | Aerospace, automotive, construction, sporting goods | Construction, automotive, aerospace, machinery |

Advantages and Disadvantages:

Composite Materials:

Advantages:

- High Strength-to-Weight Ratio: This makes them ideal for applications where weight reduction is crucial, such as aerospace and automotive industries.

- Tailorable Properties: The properties of composites can be precisely tuned by varying the matrix, reinforcement, and their volume fractions.

- Design Flexibility: Composites can be molded into complex shapes, offering design freedom.

- Corrosion Resistance: Many composites exhibit excellent corrosion resistance.

Disadvantages:

- Anisotropy: The properties of composites can vary depending on the direction of loading, due to the orientation of the reinforcement.

- Damage Tolerance: Composites are susceptible to damage, and defects can propagate easily.

- High Fabrication Costs: Manufacturing composites can be more expensive than traditional materials.

- Recycling Challenges: Recycling composites can be complex and challenging.

Alloys:

Advantages:

- High Strength and Durability: Many alloys possess exceptional strength and durability, making them suitable for demanding applications.

- Good Ductility and Formability: Alloys can often be easily shaped and formed into various geometries.

- Established Manufacturing Processes: Well-established and cost-effective manufacturing processes are available for many alloys.

- Recyclability: Many alloys are easily recyclable, making them environmentally friendly.

Disadvantages:

- Limited Tailorable Properties: Modifying the properties of alloys requires careful selection of alloying elements and heat treatments.

- Corrosion Susceptibility: Some alloys are susceptible to corrosion, requiring protective coatings or specialized designs.

- Density: Compared to composites, many alloys can be denser, increasing weight in certain applications.

- Potentially High Cost for Specific Alloys: While many are cost-effective, certain high-performance alloys (e.g., titanium alloys) can be expensive.

Conclusion: Choosing the Right Material

The choice between composite materials and alloys depends heavily on the specific application requirements. If high strength-to-weight ratio, design flexibility, and corrosion resistance are paramount, composites might be the preferable option. However, if superior ductility, established manufacturing processes, and ease of recyclability are more critical, alloys could be the better choice. Factors like cost, environmental considerations, and the required performance under various loading conditions must also be carefully considered. Understanding the fundamental differences and advantages/disadvantages of both composite materials and alloys is crucial for making informed material selection decisions in engineering and design.

Latest Posts

Latest Posts

-

How Far Is 20 Kilometers In Miles

Mar 31, 2025

-

How To Find The Perimeter Of Semicircle

Mar 31, 2025

-

What Is The Least Common Multiple Of 11 And 2

Mar 31, 2025

-

How Do You Calculate The Percent Abundance Of An Isotope

Mar 31, 2025

-

Equation Of A Circle Calculator Given Two Points

Mar 31, 2025

Related Post

Thank you for visiting our website which covers about Difference Between Composite Materials And Alloys . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.